More than 100 years committed to technical progress has made us the leading manufacturer in the fields of variable AC drives, servo drives, control technology and robotics.

Energy Recuperation for Yaskawa Robots

Efficiency and Sustainability Enhancement

What is Energy Recuperation?

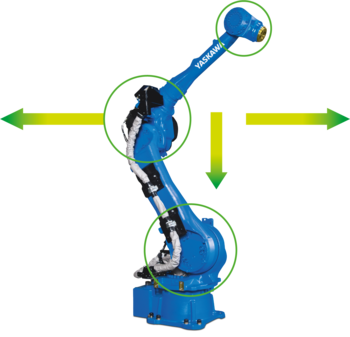

Energy Recuperation is the process of reusing energy that would be lost as waste, i.e. heat released into the environment, during robot operation. Industrial robots perform many downward or sideways movements in their very diverse tasks - such as handling, palletizing or machine tending, in which the servo motors can dissipate energy and potentially generate electricity. So far, with older or other robot models on the market, the resulting energy is converted into waste heat by electrical resistors and released unused into the environment.

Unrivaled solution: recovering braking energy

With MOTOMAN robots

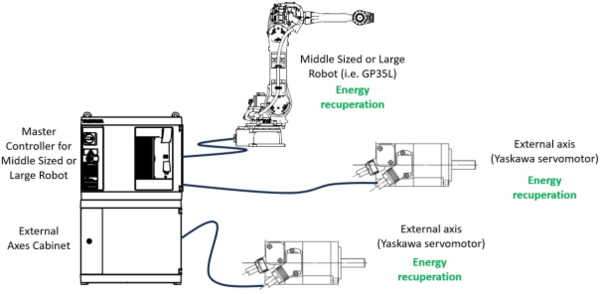

We offer a technical solution for feeding robot and track/gantry/positioner braking energy back into the power supply system – as standard and without additional hardware. All larger MOTOMAN robots of the series from 35 kg payload and the current YRC1000 robot controller are able to convert kinetic energy from downward and sideways movements directly into 400 V alternating current at 50 Hz and feed it back into the grid. Depending on the motion profile, this considerably reduces the energy requirements of the robot.

This unrivaled technical solution is the result of Yaskawa’s decades of experience as a manufacturer of drive technology – all servo drives and

control packages are optimally adapted for use in our industrial robots.

The MOTOMAN robots tap further efficiency potential with their streamlined and compact design with low moved masses, and the rapid application of brakes during pauses in motion in order to switch off the active position control when not in use. Intelligent operation concepts of the user, including, for example, the automatic shutdown of the robots during planned breaks, also contribute to energy savings.

Recuperation of external axes – middle sized and large robots

Results of Energy Recuperation

- How high the savings are in detail depends of course largely on the task and the individual movement pattern of the robot. Savings range from 8% to 25%.

- This can lead to annual feed-ins of around 2,800 KWh, 1,600 kg CO2

- Yaskawa has only comparable solution on the market

- With this unique technical solution, Yaskawa is demonstrating its experience as a drive technology manufacturer – after all, all servo drives and control packages are products from our own company and are therefore optimally adapted for use in industrial robots.

Reasons for Green Yaskawa products

- Saving of electrical energy and decreasing the CO2 footprint is a main target worldwide

- Extensive energy usage contributes to greenhouse gas emissions and places a strain on the existing energy infrastructure

- Automation of production processes brings quality and efficiency to manufacturing and optimization of production processes improves chances to reach company goals and to assure sustainability

- Robotization brings flexibility to manufacturing processes and cover repetitive tasks with high accuracy