Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

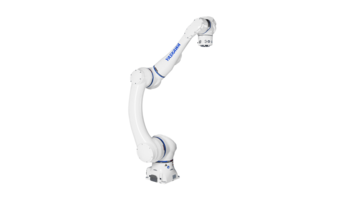

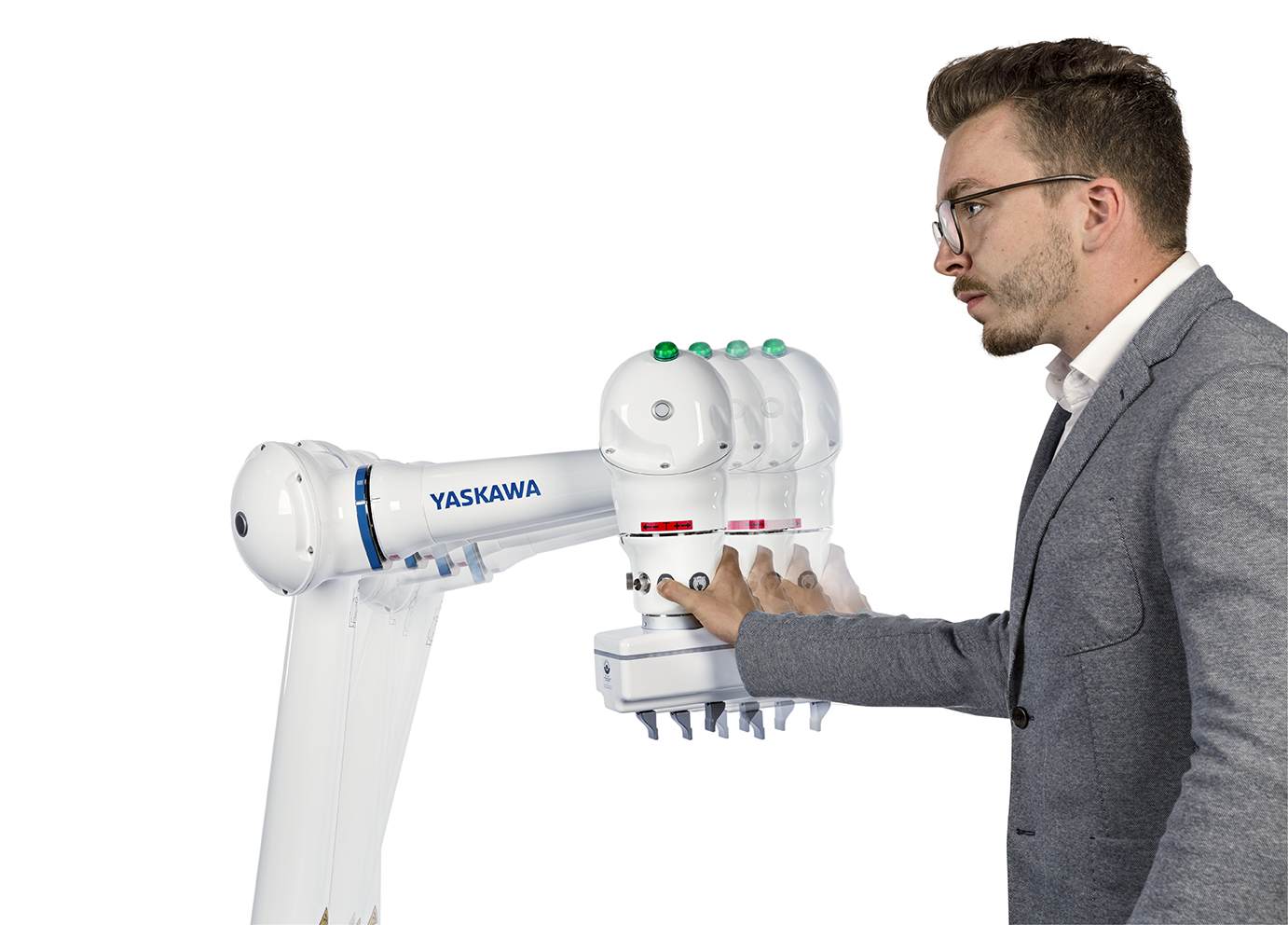

HC Series Cobots - Your New Work Assistants

When you hear the term “industrial robots”, you may associate this with images of welding or painting processes at automobile plants. Now however, robots are used in many more fields and across applications including logistics, pharma and food manufacturing. In recent years, skilled labour shortages at manufacturing sites have become an increasing challenge globally so that automation, utilizing robots has become increasingly significant. In addition, the needs for the utilization of robots are diversifying these days as we assign multiple jobs to one robot, not just make it repeat a simple single task as before.

Nevertheless, there are still challenges for the small and mid-sized company to install robots as the working area for humans has to be separated from industrial robots by a safety fence, which requires sufficient space and additional installation costs. The Yaskawa human collaborative robot (HC10) is a new generation of robotics that is capable, affordable, versatile, simple to use and built with the industrial strength for which Yaskawa products are known. These robots are for customers looking for easy automation, a robot to automate tasks, that can work in close proximity to humans.

Easy To Program

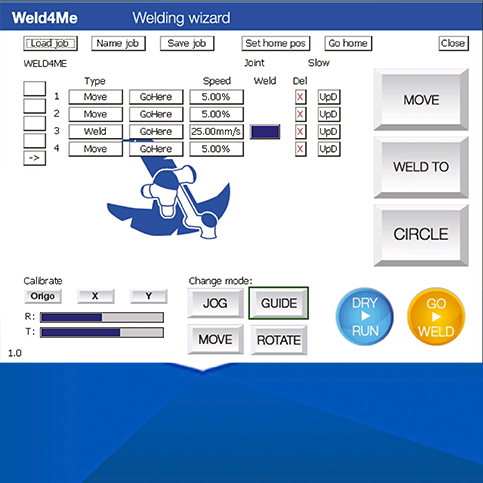

Application-specific wizards

Application wizards are designed to simplify the steps and decisions you need to make in order to have a working robot program. It is about hand guiding the tip to a sequence of positions, recording and playing back the sequence.

Intuitive Direct Teaching (DT)

The perfect entry into programming. Simply move the robot flange by hand, record the motion points and operate the gripper actuation by pressing the respective DT buttons. The code is automatically generated in the background on your pendant.

Innovative Smart Pendant

The 10-inch touchscreen is operated like a smartphone with features such as a blend in sidebar, large intuitive buttons or split screen mode Seamless direct teaching integration makes programming with collaborative robots particularly user-friendly.

Classic Teach Pendant

This pendant has the proven performance for complex tasks. With full access to our function portfolio, the robust industrial design and the combination of haptic feedback and touchscreen operation, programming possibilities are limitless.

Interested in cobots and their application? How about arranging a free consultation with our cobot experts?

Sophisticated Safety with 25 functions and PL d Cat. 3

Torque Sensors in each Joint

Each joint is monitored by a single sensor system, that can sense its environment. When a collision occurs, the HC executes a safe stop. The robot‘s sensitivity is adjustable to adapt to the respective production environment.

Retract & Clamp Release Function

Our unique safety technology detects clamping situations and reacts before someone gets hurt. An immediate robot retract reaction reduces the applied pressure, while the following free drive motion enables the operator to free himself.

Pushback Function

The robot can be pushed away smoothly while moving, i.e. when the robot gets in the way of the operator during manual work. After push back, the robot moves back to it‘s last position and continues his work.

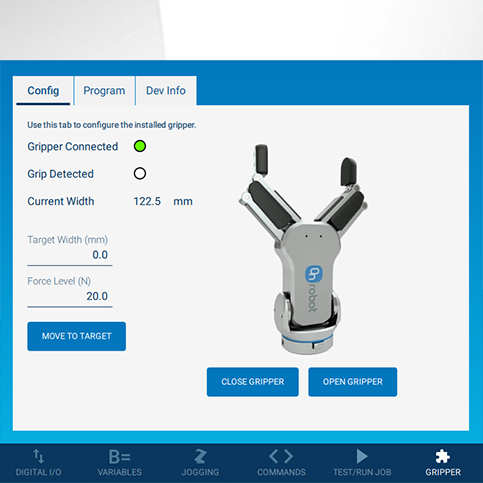

Plug & Play with the Yaskawa Ecosystem

Yaskawa has partnered with the leading gripper and accessory manufacturers to provide our customers an ecosystem of 120+ ready-to-use compatible and plug & play products. By this, Yaskawa helps customers - that are new to robotics - to start their automation story today, as well as robot experts to find new possibilities of intelligent robotic systems.

1. Receive your ready-to-install package

2. Install the gripper on your robot

3. Configurate on the Smart Pendant

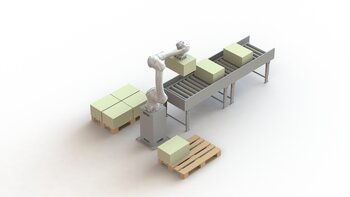

Next Level Palletizing

With a payload of 12 kg and a reach of 1,250 mm, the NHC12 manipulator is the right choice for a wide range of collaborative handling and assembly tasks. As part of the MOTOMAN NEXT platform, it is suitable for adaptive automation applications in which robots use sensors (e.g., cameras, force sensors) to detect, understand, evaluate, and autonomously respond to new situations and workpiece variants.

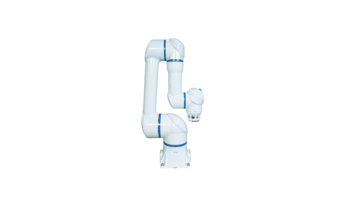

The Cobot has six axles and a load capacity of 30 kg. It also offers a reach of 1,700 mm. This makes the Cobot ideal for palletizing applications. For palletizing tasks without safety fences, such as end-of-line packaging technology, it is the largest cobot in Yaskawa's HC series. The Smart Pattern Wizard palletizing software and the Yaskawa EcoSystem Plug & Play solutions are further advantages of the cobot.

The 6-axis robot has a load capacity of 20 kg. Thanks to its reach of 1,900 mm (effective 1,700 mm), the Cobot is ideal for palletizing. The Cobot can be guided by hand as well as by the intuitive Smart Pendant. This enables hand guidance via the wrist. This allows positions to be programmed quickly and easily. The cobot can therefore also be used in scenarios where newcomers are involved.

HC20DTP Application Bundle

You are looking for help creating your palletizing application with HC20DTP?

Just check out our palletizing application landing page with our palletizing configurator.

Space-saving Palletizing with HC10

The operating range of HC robots is designed to reach the long side of a pallet without the need of a robot pedestal.

HC10 TECH SPECS:

- Optimal palletizing specs with 10kg payload and 1379mm reach

- Fenceless operation due to internal torque sensors

- Fast cycle times even in collaborative mode

- Sophisticated safety features

- IP67 protection, food grade grease and powder-coated surface as option for operation in sensitive environments such as the food industry

CUSTOMER PROJECT SUCCESS STORIES

““For us at Segbert, the decision was made in favor of the Yaskawa cobots because Yaskawa, as a well-known robot manufacturer, supplies reliable cobots that offer an ideal mix of high-quality mechanical engineering and a particularly flexible and compact design. The Yaskawa cobots therefore meet essential criteria for our palletizing and automation solutions.”

- Klaus Segbert, Managing Director Segbert GmbH & Co.KG

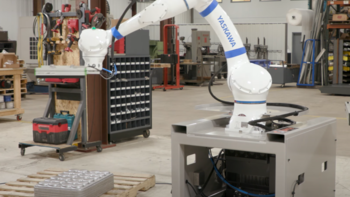

Easy Welding with Weld4Me

Weld4Me CE Cell

The Weld4Me CE Cell is the ultimate cobot welding package. As the market leader in robotic arc welding, we have carefully selected a set of high-quality products to provide you an easy entrance in robotic welding.

TECH SPECS:

- CE marking incl. risk assessment

- IP67 protection against welding spatters

- Easy programming with welding wizard and direct teach

- 2000mm x 1000mm welding table

- Exhaust system

- Welding power source

Weld4Me Mobile Station

As an alternative or supplement to manual MIG/MAG welding

with air-cooled welding equipment, the Weld4Me robot station

offers all the advantages needed.

TECH SPECS:

- IP67 protection against welding spatters

- Easy programming with welding wizard and direct teach

- Easy to integrate due to small footprint

- Easy to relocate and start up again

BENEFITS OF COLLABORATIVE WELDING

Faster Turnaround

Easy set-up and teaching enable you to say yes to more jobs, deliver them on-time and be more profitable.

Steady Staffing

Short-handed? No problem. Welders can teach the cobot repetitive jobs, then move on to more skilled welding tasks.

Consistent Results

Let your cobot handle long seams and heavy deposition to maintain quality where physically-demanding work often falls short.