Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

Warehouse automation - when robots manage complexity.

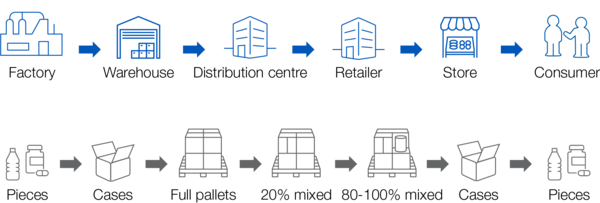

Moving goods from factory to consumer is no longer a straightforward task.

Modern warehouses face growing challenges from a wide mix of stock keeping units (SKU:s), tighter delivery expectations with a fluctuating demand, limited space, and labour shortages. On top of that, they must efficiently manage large volumes of pallets, empties, and essential packaging materials.

This complexity demands precision, scalability, and adaptability ─ qualities that robotic automation excels at delivering. Robotic automation from Yaskawa is well suited for seamless integration into WMS systems (communication interface, bus/protocol/ID).

Boosting productivity without raising commissioning costs.

Increasing warehouse productivity does not have to mean higher costs or longer commissioning times. In collaboration with our technology partners, Yaskawa delivers flexible, high-performance solutions that optimise the flow of goods and information.

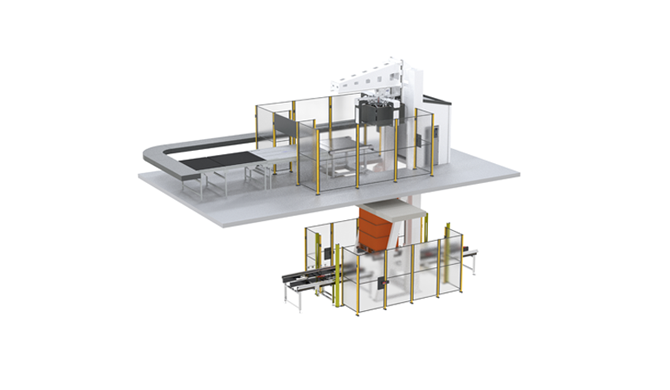

By combining high performance robots, intuitive software, and cutting-edge vision systems, we offer turnkey solutions that enable high precision and faster cycle times even for complex tasks such as:

- Piece picking

- Case picking

- Layer handling

- Mixed case palletising

- Random box de-palletising

These systems are designed for quick deployment and seamless integration, helping you scale operations efficiently while keeping implementation time and cost under control.

Safer, and with greater added value.

Warehouse tasks like picking, sorting, and palletizing are physically demanding and often repetitive making it harder to retain staff in these roles. Standing all day and handling various objects can also pose safety risks, highlighting the need for better working conditions and more meaningful career opportunities.

With intelligent robots that can identify objects and adapt in real time, warehouses can automate labour-intensive tasks. This not only improves safety but also allows employees to shift their focus to higher-value, less physically demanding activities which are enhancing both job satisfaction and operational efficiency.

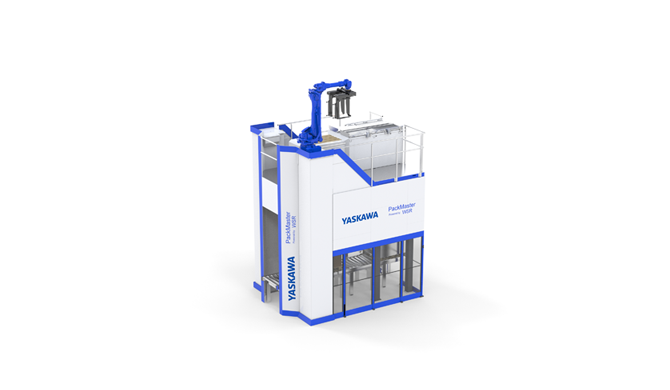

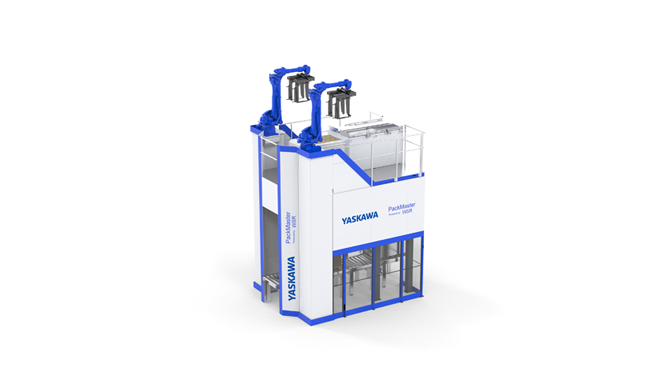

Turnkey solutions for mixed palletising or layer handling.

Using our modular design concept, we combine the MOTOMAN industrial robot with vertical and horizontal motion in order to create turnkey solutions for advanced palletising and packaging requirements. With a turnkey system like Packmaster you can start off with manual operation and simply add one or two robots at a later stage.

More than just a robot supplier.

At Yaskawa, we go beyond delivering robots ─ we engineer complete automation solutions. With deep expertise in designing innovative robot grippers, drives and motion control, vision systems, and application software, we create systems that are not only powerful but also practical.

Our products are tried and tested across a wide range of applications and are fully integrated into our robotic platforms. In collaboration with leading technology partners, we ensure that our solutions are flexible, scalable, and future-ready.

Additionally, our third-party components are compatible plug-and-play products, making them ideal for seamless integration into warehouse automation environments. This enables faster deployment, reduced commissioning time, and reliable performance from day one.