Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

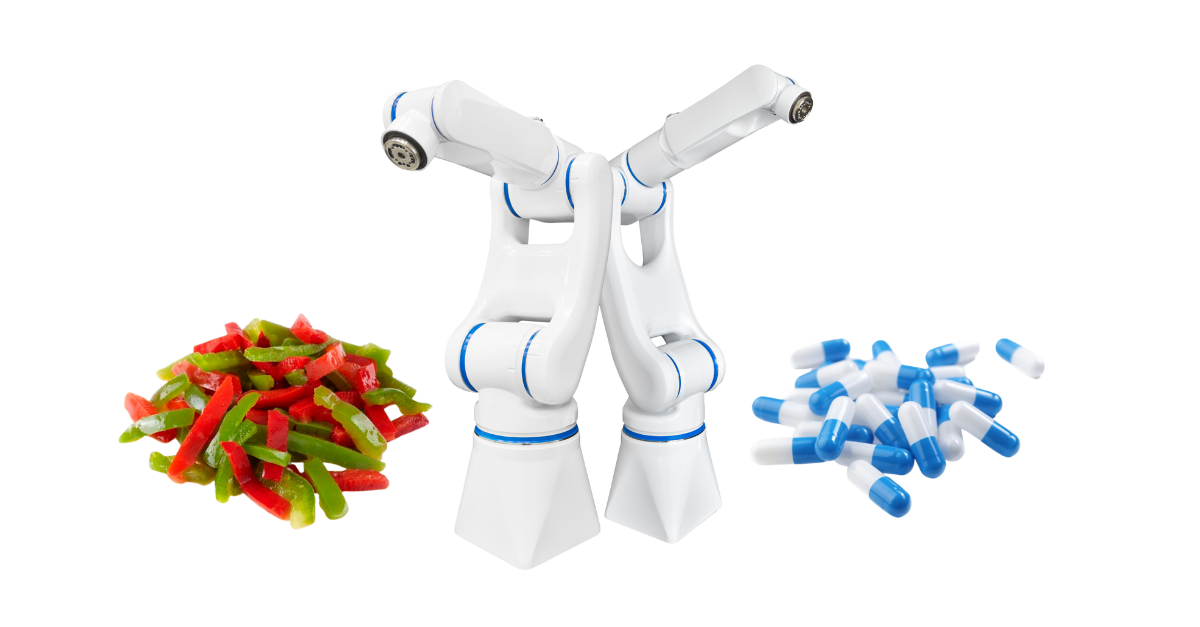

Automating the food industry

Highest hygiene standards | Certified food-grade design

Robots in the food industry - hygienic and efficient

From reducing downtime and minimising waste to meeting increasing consumer demands and hygiene regulations, the use of robots in the food industry is the key to unlocking almost limitless opportunities while creating a more sustainable world. The implementation of robotics and automation in the food sector offers great potential for improved safety, quality and profitability by optimising process monitoring and control.

With food safety front of mind, Yaskawa has introduced the most hygienic robot on the market. The HD (Hygienic Design) robots are capable of performing a wide range of handling tasks in hygiene-sensitive environments.

Made in Europe! Our robots are made in Europe, guaranteeing short delivery times and cost efficiency.

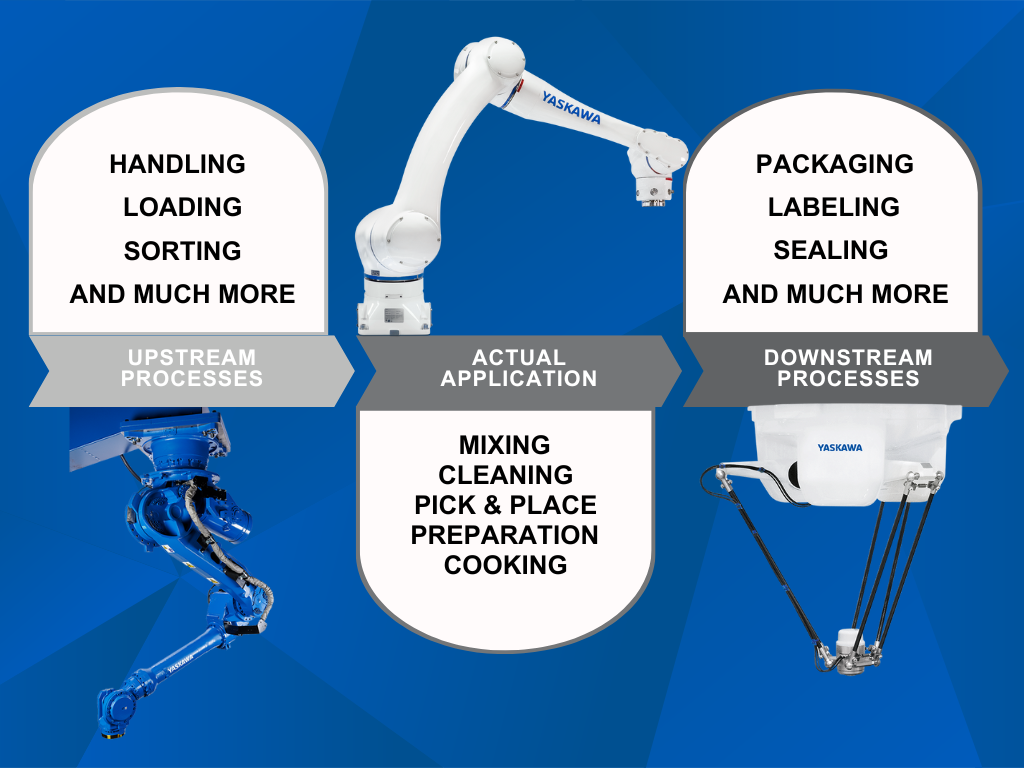

Automating every step of the process

Every step of the processing of food can be automated, saving labour costs and ensuring consistent quality and efficiency from beginning to end. Whether it is an upstream process - handling, loading, pick & place - or a downstream process - packaging, sealing, marking - or the actual food preparation, Yaskawa has you covered with over 100 robot models that can be used for many different applications. We even have robot models that can handle raw food with the highest level of food safety.

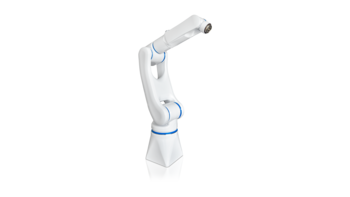

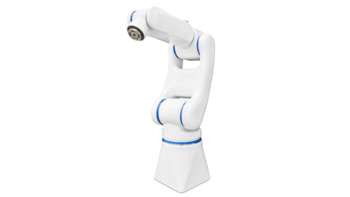

Highlight: HD Robot Series - the most hygienic robots in the world

With its modern design, the HD robot series meets the strict standards for applications in the food, life sciences, laboratory automation, medical and pharmaceutical sectors.

These robot models are are easy to clean and resistant to commonly used disinfectants and disinfection processes. With an antimicrobial smooth surface, they have a special coating with excellent mechanical and chemical resistance. This prevents paint particles from ending up in the food products, a common occurrence in the food industry up to now.

The hygienic design includes an encapsulated housing without protruding screws, a unique axle sealing design and internal cable routing. Naturally, only Food Grade Grease has been used in these robots and with a protection class of IP69K, they really are in a league of their own.

EHEDG Membership

Yaskawa is a proud member of the European Hygienic Engineering & Design Group (EHEDG). By joining this extensive network, we are committed to supporting the EHEDG vision and mission. This membership allows us to influence industry trends, access exclusive guidelines, gain international exposure, and build strong, lasting relationships within the global community. With our HD7/HD8 robots, which are specifically designed for hygienic handling in the life sciences sector, we fully comply with these guidelines.

Red Dot Winner

The Red Dot Design Award is one of the largest design competitions in the world. The Red Dot Label has become established internationally as one of the most sought-after marks of quality for good design. We are therefore delighted that our HD7 robot has been honored with the "Red Dot Award: Product Design 2024". Among the numerous submissions from companies and design studios from all over the world, the outstanding quality and design of the HD7 convinced the jury, consisting of around forty international experts.

What is Food Grade Grease and why is it important?

Products used in food processing must meet strict standards to ensure safety and quality. Once food manufacturers have invested in quality equipment, they'll also want to ensure that it runs efficiently. While the guidelines may seem daunting, it is in the best interest of food companies to make every effort to comply with them to minimize risk exposure.That means using the right lubricant.

Food grade grease can play a significant role in preventing costly damage brought on by severe operating conditions. Food processing companies must ensure that lubricants are suitable for incidental contact with food while meeting the highest health and safety requirements.

Food grade lubricants are specialized products designed for use in food processing environments where there might be incidental contact with food. They play a crucial role in maintaining the integrity and safety of food products. Their use ensures that food manufacturing operations comply with global food safety standards, minimizing risks of contamination and supporting public health.

Application cases in the food industry

Exciting applications and satisfied customers

Discover interesting application examples from the food industry and see our perfectly tailored solutions for yourself.

Cheese production with robots

Food-grade-grease robots ready to automate your food processes

GP FGG Series

Multiple payload options, highest speeds and permissible robot wrist torque values

- Handling of a wide range of products and mounting of different grippers with payloads of up to 180 kg

- Optimized acceleration and braking behavior, enabling an improvement in cycle times

- Specifications like high IP65/67 (dust/liquid proof) protection rating, food grade grease lubrication in all joints, and a special drip proof coating allows the robot to be used in food related applications.

Contact us now

Do you have questions about a specific application or one of our robots? Are you planning an interesting automation project or are you already in the planning phase and would like to make use of our excellent team of development engineers and our decades of expertise in system construction? Simply fill out the contact form and we will get back to you as soon as possible!

Here will be a contact form

Our Yaskawa services at a glance

Yaskawa accompanies you throughout the entire product life cycle with customized services that are precisely tailored to your needs. Our aim is to maximize your system availability and productivity and keep them at a high level in the long term. Thanks to our global service network, Yaskawa is always close by to ensure your success.

Technical customer service

For quick and competent advice, our specialists are available 365 days a year via our technical hotline.

Yaskawa EcoSystem

Our plug & play solutions enable numerous use cases for robots and cobots. Find out more about the Yaskawa EcoSystem here.

In house repair

With Yaskawa, you have direct contact and access to the manufacturer of the robots, controllers and drive technology.

Yaskawa offers you professional repairs with OEM parts and warranty at fair prices. In addition to sending them in for specialist repair, we also offer you a repair exchange service and individual overhaul of your Yaskawa robots and components.

Engineering

Would you like to modernize existing Yaskawa products and systems or adapt them to changed requirements? Our team will be happy to take on the engineering and implementation of your modernization projects.

Do you need support in planning and implementing projects with robots or cobots? Here too, our team of experts is on hand to advise you. We work with you to develop new, customized robot systems and support you in the implementation and initial use of your new robots.

On-site service

Our service specialists will be happy to assist you with the integration of our products into your production, necessary repairs, preventive maintenance work and application-related programming. We will be happy to inform you about our customized service and maintenance contracts or prepare an individual offer tailored to your needs.

Whether you want to buy an industrial robot, are interested in industrial robot prices or want to know how to program industrial robots, Yaskawa is at your side with comprehensive know-how. Our solutions cover everything from small industrial robots to specialized industrial robot arms.