Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

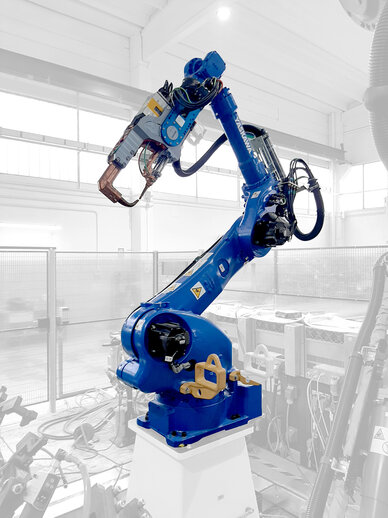

New MOTOMAN SP series of spot welding robots

Faster, better and more efficient

Our new generation of energy-efficient spot welding robots that cover a payload range of 80 to 235 kg, are now available. Together with the handling robots of the GP series, we offers a full portfolio of robots for spot welding cells and body construction. Improvements are to be found, in particular, in the controller and drive units (latest controller generation YRC1000), in the function packages and path planner, which has been further optimized for spot welding motion patterns, culminating in fast cycle times.

The slim and lightweight design, the latest Sigma7 servo technology in conjunction with a standard condenser unit for the recuperation of braking energy result in outstanding cycle times. With typical spot welding motion cycles (fast/short point-to-point positioning movements) substantial energy/CO2 savings are possible, depending on the movement pattern.

Of particular interest with Yaskawa has always been the option of synchronous control of master/slave systems and positioners with only one controller – resulting in savings in hardware, e.g. communications integration (fieldbus/safety/IoT), and cycle time optimization potential on the software side due to the perfectly synchronized or superimposed movements combined with less programming work.

Compact Motoman SP80 and Motoman SP100 spot welding robots

Motoman robot models SP80 and SP100 are compact spot welding robots with payloads of 80 or 100 kg for servo-controlled lightweight welding guns. With this technology the extremely compact, cycle-time-optimized, energy-efficient and low-cost welding cells can be installed in the most confined spaces. These robots are suitable, e.g. for compact spot welding lines in body construction with a high robot density, for cost-effective welding of small subassemblies and for space-saving mounting on a positioner.

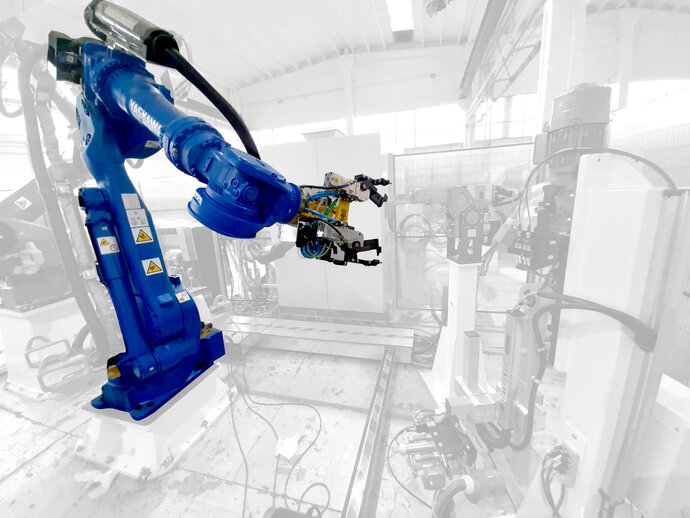

Six high-performance spot welding and handling robots

The other six SP models are spot welding robots with the classical spectrum of payloads and ranges for spot welding between 150 and 235 kg. These robots are also ideal for workpiece handling in conjunction with the control of stationary welding guns.

Two robot models of the SP series with a particularly large range of over 3 m are of the console type, i.e. they have an extended working range below installation level when mounted in an elevated position, e.g. on a steel structure.

Spot-welding robots of the SP series are suitable for a wide range of standard spot welding guns and grippers, in particular for servo-controlled welding guns as an integral 7th axis with robot-assisted gun equalization. The mechanical design of the SP robot manages without a mechanical counterweight balancer; small moving masses permit greater acceleration and speeds. The stable wrist is ideally suited to small and fast positioning movements, as are common in spot welding applications.

A further feature of the Motoman SP series is the optional C adapter on the wrist flange – for optimum low wear and service-friendly routing of cable packages.

Contact for readers’ enquiries:

Tel. +49-8166-90-0

Fax +49-8166-90-103