Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

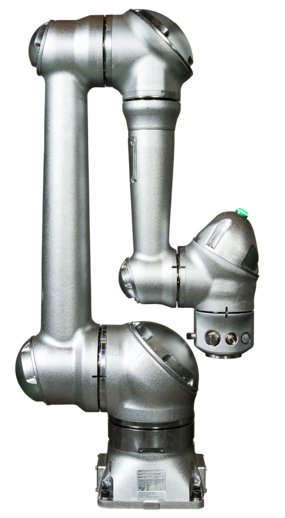

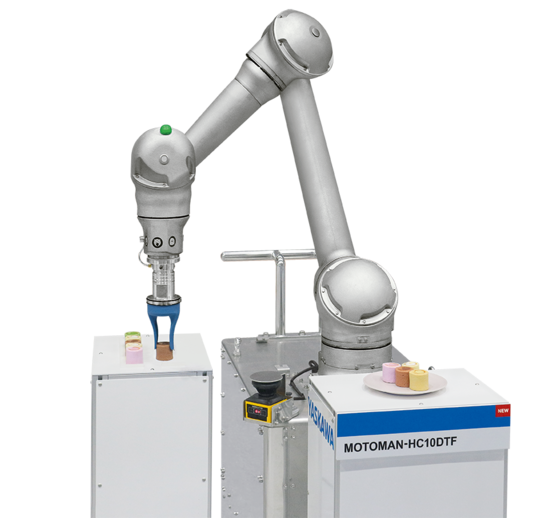

MOTOMAN HC10DTF - New hybrid Yaskawa cobot for the food and pharmaceutical industries

The new MOTOMAN HC10DTF extends the Yaskawa portfolio of hybrid cobots to include an industry-specific version for the food and pharmaceutical industries.

Like the currently available HRC-capable designs HC10DT IP67 and HC20DT IP67 the new product is also in dust- and watertight according to protection class IP67. However, in addition the new robot has a powder-coated surface that permits the use of alkaline and acidic cleaning agents. In addition, it uses food-safe lubricating grease. The MOTOMAN HC10DTF thus fulfils the stringent hygienic requirements of the food and pharmaceutical industry pursuant to ISO Class 5 or EG-GMP Class A.

It can therefore be used, for example, for palletizing primary packaged food or handling samples in laboratories. Employees can be relieved of physically stressful work, e.g. stacking larger cardboard boxes or other stackable goods. The robot assumes the task of lifting these heavy loads, improving workplace ergonomics, and personnel can be deployed to cognitively more challenging activities.

HRC-capable hybrid robot

Like all models in the MOTOMAN HC series, the new HC10DTF is also an HRC-capable hybrid robot. This means that it can be also be operated in hybrid mode by connecting external safety technology, e.g. a laser scanner. As a result, the cobot alternates between collaborating, reduced and full speed, in order to achieve a maximum cycle time depending on the distance to the operator.

Due to six integrated torque sensors that enable flexible interaction between the robot and its environment, the newly developed model ensures the required safety in direct contact with the operator. These monitor any external forces that may occur, guaranteeing the highest level of safety in direct human-robot collaboration. In industry mode, i.e. when no human being is present, the robot achieves top speeds of up to 1 m/s. Area monitoring of this type can be implemented with external safety sensors such as laser scanners.

The hybrid mode, i.e. switching between collaboration and industry mode, guarantees maximum economic efficiency with minimum space requirements. This is particularly advantageous when integrating into existing systems where space is at a premium and the use of safety guards is impractical, such as end-of-line stacking.

Contact readers’ enquiries Yaskawa:

Tel. +49-8166-90-0

Fax +49-8166-90-103