Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

Polet buys third Yaskawa robot

At Polet - De Pypere in Ardooie, Belgium, the production area is increasingly turning blue. In addition to a Yaskawa robot welding cell through which many different products go, two other Yaskawa robots are now also at work there to weld and paint certain Polet - De Pypere products. This modernization has resulted in the necessary improvements in both efficiency and productivity.

Forward thinking

Polet - De Pypere is a supplier and manufacturer of professional tools and hobby tools for garden, construction and industry: spades, shovels, hoes, weed cutters and much more are made by this completely Belgian company that already forged the first spade blades in 1865. From a simple blacksmith shop, the company has grown into an industrial company that continuously invests with a forward-thinking view in automating and optimizing its products while respecting the old technology. An ArcWorld cell with turntable and 2 positioners had already been purchased for this. Recently, a paint robot and a second welding robot, type MA1440, were added to the Yaskawa robot range at Polet.

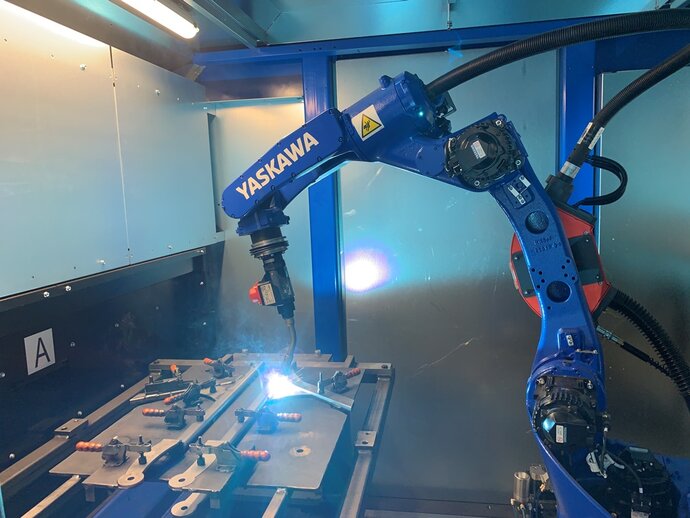

The standard ArcWorld welding cell is used for welding smaller pieces with mainly short welds. The robot makes many movements with little welding. “The concept really appealed to me. The operator no longer has to run around. Loading and unloading the cell is not at all labor-intensive,” says Stefaan Denolf, technical director. Sometimes twenty pieces must be placed in a mold for welding. Without the ArcWorld cell this meant that the operator had to walk a lot, but fortunately this is now a thing of the past.

Compact

“The cell is compact: a hose package runs through the arm of the robot. This allows the robot to handle very fast movements without having to take the hose package into account,” Denolf explains about the further advantages of the ArcWorld cell. "The price was also very competitive."

In March, Polet - De Pypere moved to a new location where four new machines have been installed, including the ArcWorld cell. RoboFlex, partner of Yaskawa, has built in the Fronius CMT power source and hose package. They also provided a number of days of training, followed by another day of training from a Yaskawa trainer. At the moment, 50 different products are being welded in the ArcWorld. The CMT welding process allows for virtually spatter-free welding, so that practically no post-processing is required.

Welding and spraying spades

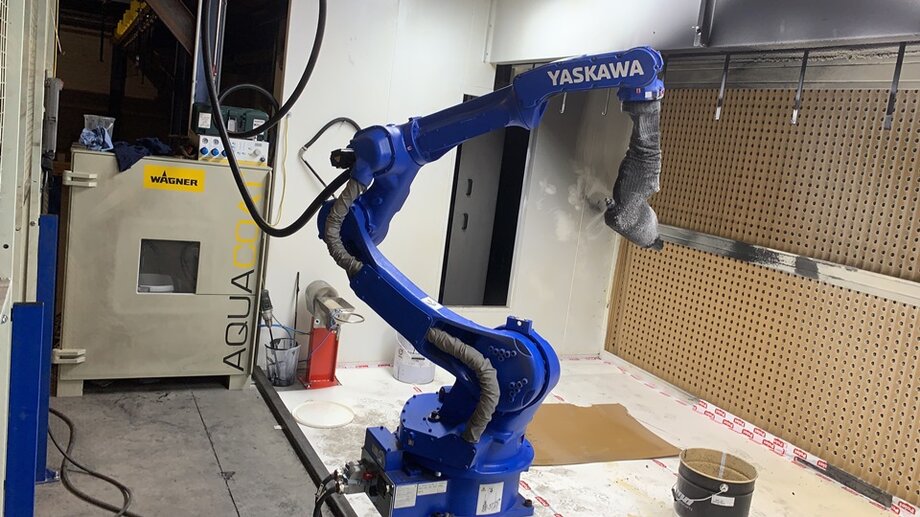

In addition to the welding cell, there is also a Yaskawa MA1440 welding robot that takes care of another part of the welding work. This is intended for welding spades, a very popular Polet product. The welding robot was bought to replace an old robot. The finishing of the spades is done by the most recent development: a wet paint line with a Yaskawa paint robot. This gives all articles a nice color and they are protected against corrosion.

Doubling capacity

“Because of the Yaskawa robots, I need fewer operators and a few less welders. Welders are more expensive than operators and you just won't find them. An operator is not a welder.” Stefaan Denolf speaks about a doubling in capacity. While the robot is welding or spraying, the operator can engage in loading or unloading. “So far it is just great. Our targets have been reached. The robots are very reliable. ”