Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

Robotics Software

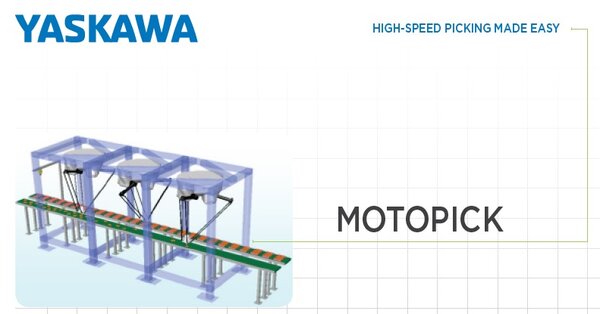

MotoPick

Order picking software for controlling picking processes

Yaskawa Europe Software Robotics Software MotoPick

Overview

MotoPick 4.0

MotoPick™ is a highly advanced, user-friendly No-Code software solution to realize conveyor-based Pick & Place robot solutions. No coding is required - all features are configured via the MotoPick PC Software Tool! Motopick Runtime runs on the robot controllers - no need for additional control hardware.

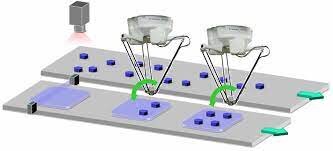

MotoPick empowers operators to setup custom pick & place applications to achieve critical cycle rates for high-speed picking applications. The MotoPick package provides building blocks to create optimal solutions for up to 16 robots, 6 conveyors and 16 tables. This powerful software can synchronize multiple robots equipped with vision to pick fast moving products off a conveyor and place it on an outfeed tray or box in an organized arrangement. It also offers pattern-based distribution of product and dynamic load balancing among multiple robots.

MotoPick precisely controls the conveyor speed. If the advancement of the outfeed tray falls behind, the infeed conveyor speed can be automatically decreased and even stopped until the tray is in a packing zone. Additionally, the opposite case is supported when the outfeed conveyor speed can be decreased or stopped when the infeed parts have not arrived yet.

A robot interface board, developed specifically for MotoPick, greatly reduces the integration wiring and panel real estate required for a multiple robot cell. The robot interface board replaces the three standard breakout boards required for each robot to interface safety I/O, dedicated I/O and standard I/O. The board also provides connections for a camera and two encoders.

MotoPick 4.0 Features

- Vision Integration - multiple product part recognition. Flexible Camera Position arrangement.

- Conveyor Tracking including tray detection via external sensor. Multiple conveyor monitoring with 1 camera.

- Multi-Controller Support (FS100 and YRC1000micro). Supported Robot Models: SG Scara Series, MPP Delta Picker Series, MPK Picker Series, MotoMini, GP Series (GP4, GP7, GP8, GP12)

- Multi Robot Systems (up to 16 robots and eleven conveyors), in parallel or linear arrangement patterns.

- up to 32 different product types

- Load Distribution / Load Sharing for throughput optimization

- Asynchronous and Synchronous Multi-Pick (multiple parts pickable for one motion)

- Configurable Single and Multi Place Patterns, Grip Rule Constraints

- Feed/Place Position Priority, Pick Order or Place Order Options

- Stacked/Layered Picking and Placing

- Weight Constraints, Load Sharing for pick and place side

- Automatic Failure Recovery (continues operation when one robot out of a line is on alarm, loses power or on maintenance)

- Online Parameter Adjustment (during operation of the system)

- Multi-Controller Support (FS100 and YRC1000micro).

Find MotoPick 4.0 on the Software Download Portal

Technical Details

- Product Type

- Application Software

- Mobile App

- x No

- Operating System

- x No

- Min. required CPU

- x No

- Min. required RAM

- x No

- Min. required HDD Capacity

- x No