Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

U1000

Low harmonics regenerative matrix converter

A class of its own

The U1000 is a highly efficient AC drive based on latest matrix converter technology. With full power regeneration capability, the U1000 offers great energy saving potential while sinusoidal input currents and a power factor close to one reduce stress on grid components like transformers and power lines. With an ultra-compact shape, the U1000 is the first choice for innovative, energy-efficient drive solutions with or without power regeneration.

Innovative matrix technology

Active Front End design without conventional DC bus capacitor inside.

Clean

power

Harmonic pollution (THD-i) below 5%.

Energy saving

4Q operation

100% braking power savings.

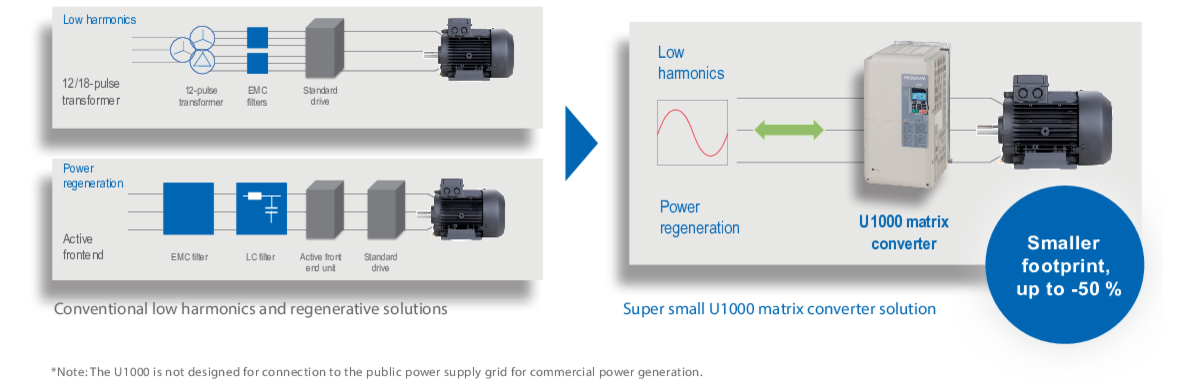

Revolutionary design for low harmonics

The U1000 has a unique and innovative design which exceeds the performance of general-purpose AC drives. This pushes the best-in-class AC drive not only to improve the application performance but it also exceeds the IEEE 519 harmonic guideline for the power quality which helps you to keep the power supply clean from any pollution.

Ultimate performance

U1000 is designed for rough applications. This extremely compact all in one solution offers optimum performance for standard and regenerative applications.

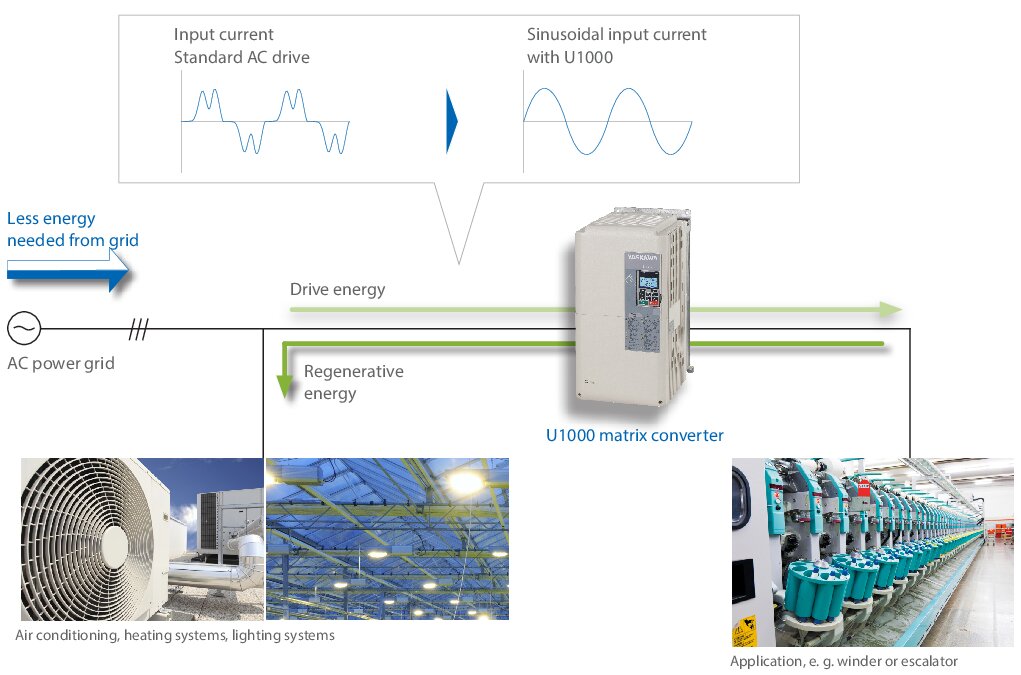

Regenerated power

The best-suited solution for regenerative applications. The U1000 eliminates the need to install external braking units and braking resistors. It returns the regenerative and the braking energy directly back to the power supply.

Built-in power regeneration

The U1000 is a very compact AC to AC drive, which means there is no DC bus inside. This innovative design does not need any braking resistor option which typically wastes the regenerative energy in heat. Now the regenerative energy can be used by other consumers in the same grid, saving total energy cost and consumption while also reducing the panel cooling system requirements.

- Saves energy

- Less heat generation, reduced need for ventilation

- No braking resistor - greatly reduced risk of fire

- Less maintenance

- Less parts

- Compact design

Compact and easy

The U1000 design advantages, compared to conventional dynamic braking solutions, continues in saving installation space (up to 50%), reduced weight and 100% save of wasted energy. All you need to connect is 3 wires in and 3 wires out.

- Smaller panels

- Very compact footprint

- Simple installation in shortest time

- Perfectly fits in existing installations - easy retrofit

Reliability and efficiency on board

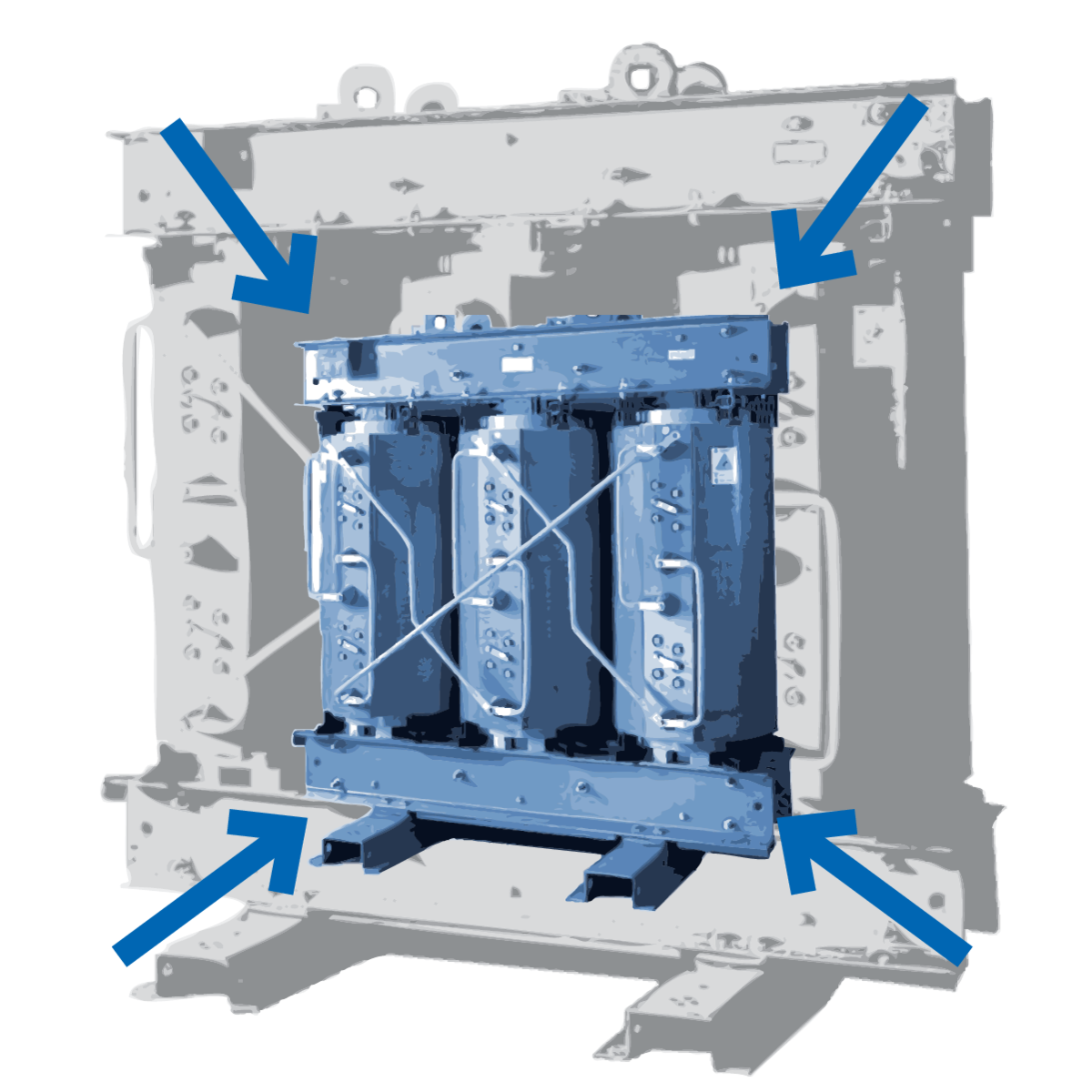

U1000 is approved for global marine installation. Compared to 12 pulse systems the Yaskawa matrix design provides significant footprint and weight savings, keeping the THDi within the IEEE 519 limits.

Clean currents

U1000 is the answer to power quality, energy savings, and system efficiency improvement. The advanced technology of the Yaskawa matrix drive combines all application key features in a single space-saving drive design reducing THDi to 5 % without the need for external transformers or heavy filtering.

- No oversizing of transformers, generators or cables

- Sinusoidal input current and power factor at ~ 0.98

- Compact installation - 3 wire in, 3 wire in

- Reduced lifecycle cost

- Reliable operation

- 10 years of maintenance-free design

100%

waste energy savings

3-5%

current distortion

0.98

power factor

Lift it up to the next level

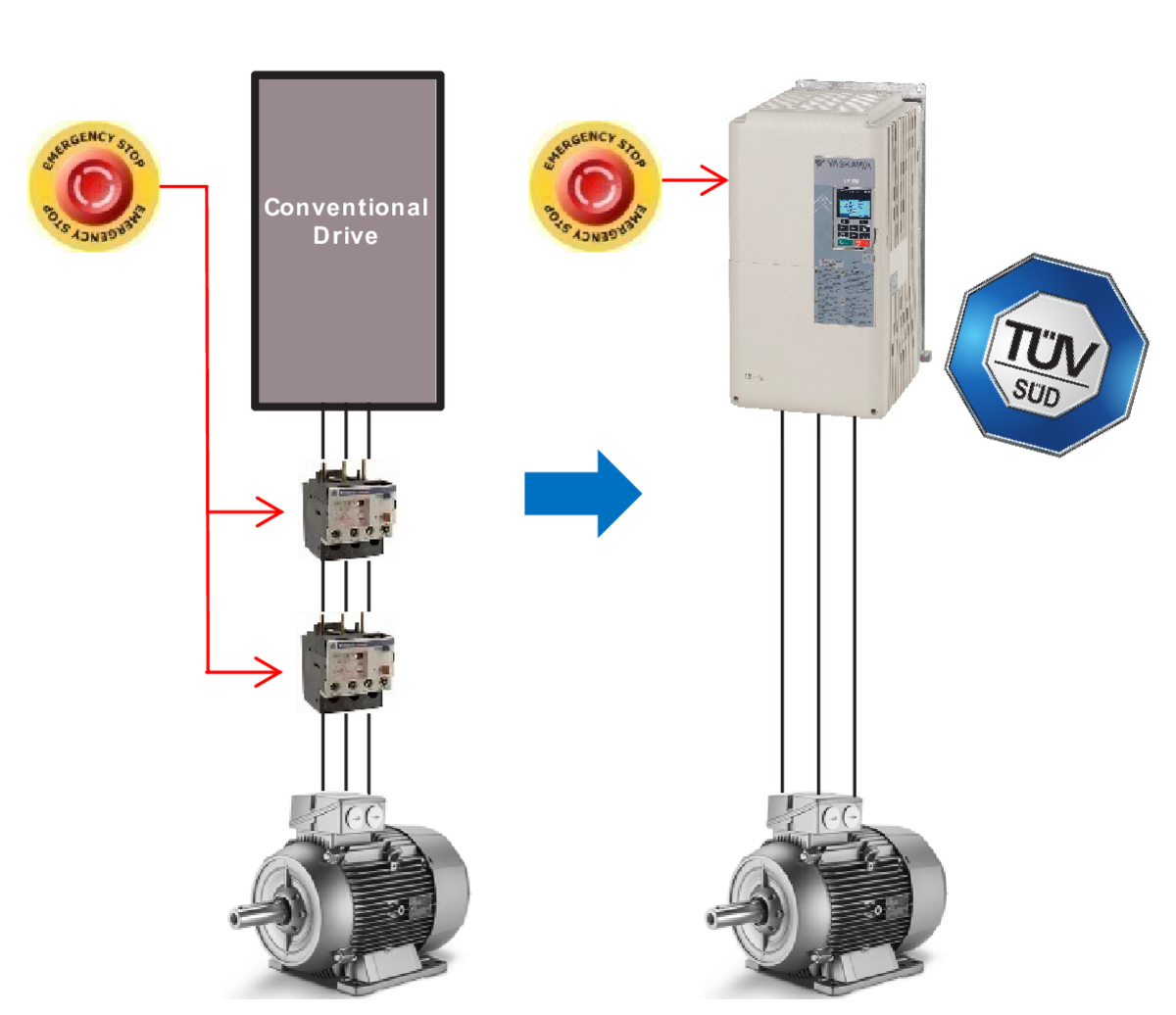

The U1000 suits perfectly to lift and crane applications. The matrix drive eliminates the need to install external braking options and offers low harmonic and clean grid power performance in one unit design. Further, the U1000 comes with SIL3, PLe, Cat3 performance making easy integration into your safety system.

Compact efficiency

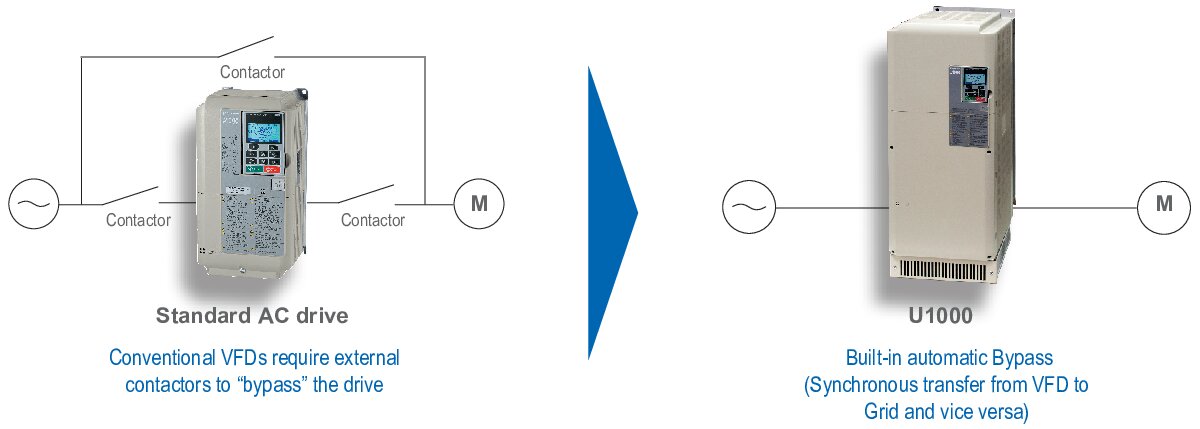

Eco mode - Built-in bypass function

The U1000 has a built-in bypass function. Whenever an application is matching the grid frequency, the U1000 can synchronize the motor to grid frequency. This built-in bypass function eliminates switching losses. It also nearly eliminates current distortion and the motor noise level will be significantly reduced.

- No need for external bypass components (no phase detectors, contactors, peripheral devices, ...)

- Reduced AC drive losses

- Silent motor operation

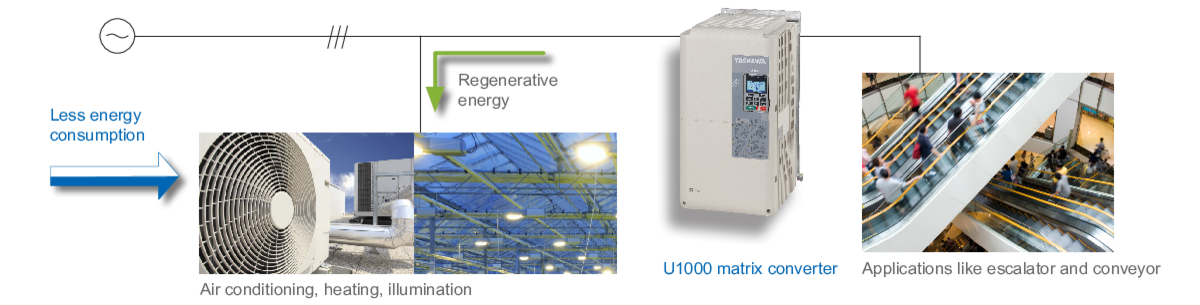

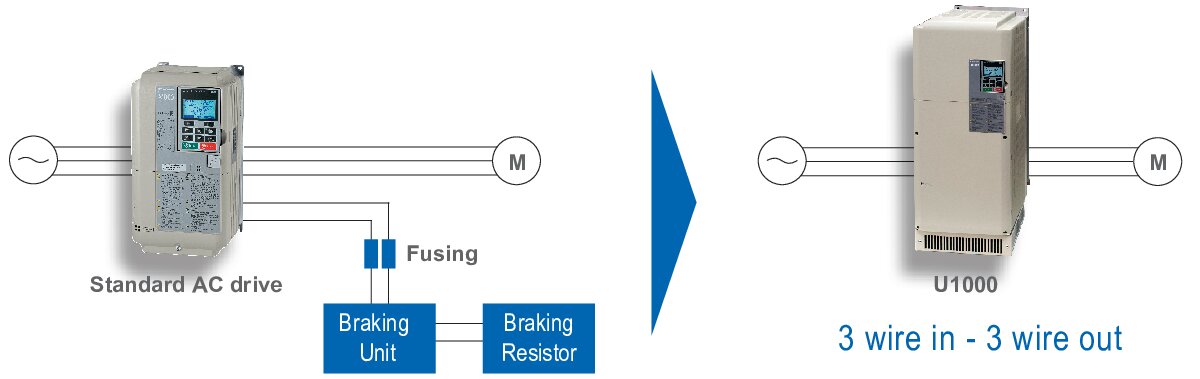

System size reduction

Conventional dynamic braking solutions with braking units and braking resistors need lots of space and cooling. The U1000 matrix drive is a simple 3 wire in, 3 wire out configuration. This advantage in design reduces the footprint of your application, saving about 50 % on wiring and weight while also saving 100 % of wasted energy and eliminating the risk of fire by overheating the braking resistors.

Eliminate components

- No additional braking units

- No additional braking resistors

- No additional fusing

50%

wiring cost reduction

50%

reduced weight

70%

reduced size

100%

reduced wasted energy

Sustainable solutions

The very compact footprint combined with low harmonic performance and reduced cooling requirement allows you to run the Yaskawa Matrix drive on smaller power grids and space critical installations.

System efficiency

The AC to AC design of the matrix drive creates a sinusoidal input current. It means the U1000 provides a power factor close to 1. This near unity power factor makes it possible to reduce losses in generators, transformers, and cables. When installing the U1000 you can even design a smaller grid capacity for new installations or add more drives to existing power lines without additional stress to the power transformers.

0.98

power factor

Modernization

The Yaskawa matrix technology has been successfully proven in the field of low harmonic, space saving and regenerative applications. The direct AC to AC design advantage makes the setup more efficient and helps to save your operation cost sharing the regenerative energy with other electrical devices in the system.

- Low harmonic (keep IEEE 519 limits)

- No need for braking units and braking resistors or

- additional fusing

- Significant reduction in panel cooling requirements

- Easy conversion from an existing to a new system

- 100 % wasted energy saved

- Designed for 10 years of maintenance-free use

Built-in functional safety

U1000 comes with a built-in dual-channel safe torque off (STO) function that meets the requirements of SIL3 and PL-e, offering an easy way to improve machine safety without the need for complex external wiring.

- TÜV certified according to

- EN/ISO 13849-1 (PL-e), IEC 62061 (SIL3)

- Simple wiring

- Less components

- Higher reliability

- Space saving

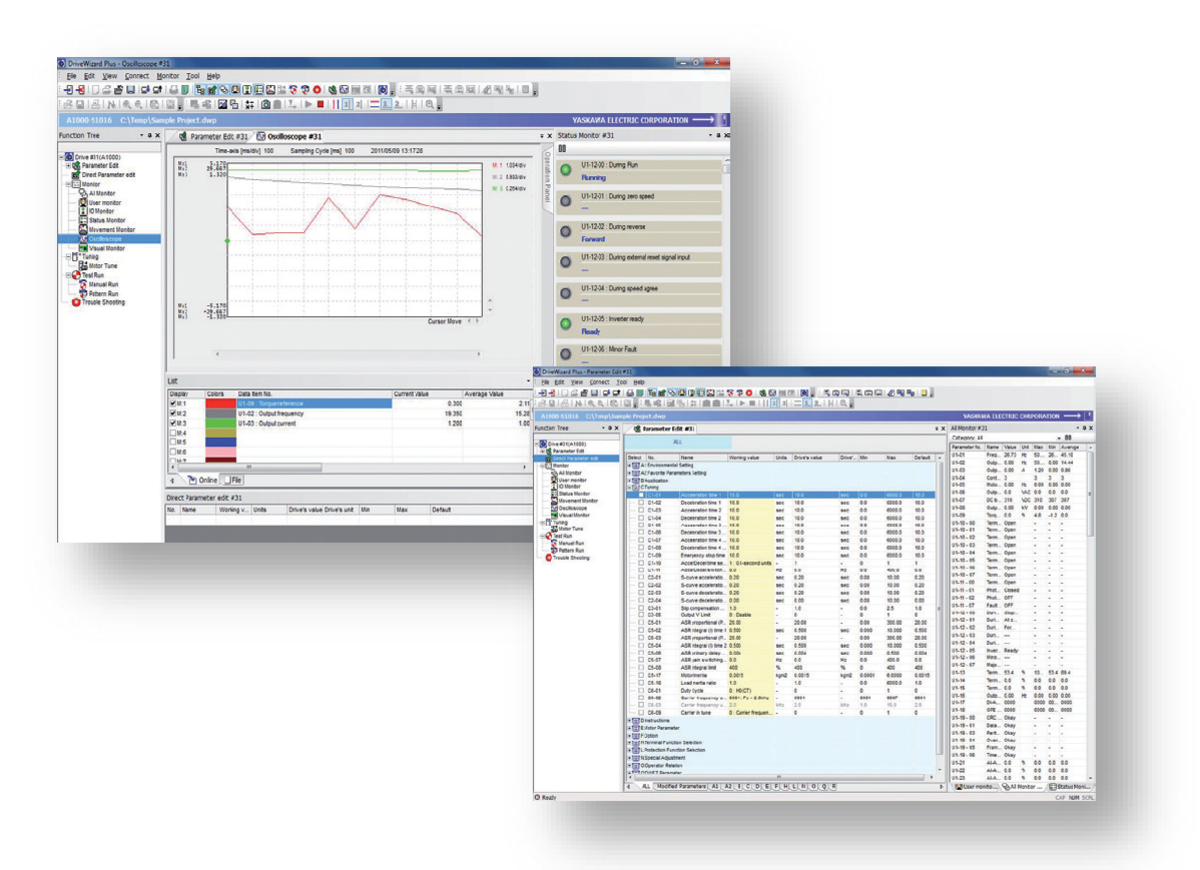

DriveWizard Plus for easy engineering

Manage the unique settings for all your drives right on your PC. An indispensable tool for drive setup and maintenance.

Edit application parameters, access all monitoring parameters, generate customized process flows and monitor the performance of the AC drives using the oscilloscope function.

- Convenient PC-based drive-setup, monitoring and diagnostic functions

- Built-in oscilloscope function

- Automatic parameter conversion from older series drives

- Online and offline parameter editing

DriveWorksEZ® for programming

DriveWorksEZ® provides users with programmable functions to customize U1000, GA500, GA700, V1000, and A1000 series AC drives to their specific applications without the need for external control systems such as PLCs. This allows users to easily access the drives via a symbol-based graphical programming environment.

- PLC or other controllers not necessary

- Easy to use

- Fast and constant scan cycles

- Flexible

- Online monitoring

- Process control

- Protected application know-how

Examples

Economically optimized water skiing facility

- No additional I/Os necessary

- No PLC required - reduced the system cost to less than 50% of the initial estimate

Highly precise positioning

- Direct access to encoder pulses

- User-defined units and monitors

Further examples

- Efficient brake sequence

- Unbalance detection in washing machines

Already know what you need?

If you already know what you need and just want to make sure we offer the perfectly sized U1000, go ahead to the drive configurator. You will also find the technical data and any downloads you might need - be it CAD files for designing your machine, manuals, CAE files, brochures or software.