Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

Yaskawa at Automatica “Robotics Technology for Smart Automation”

The current Cobot Ecosystem, MOTOMAN Robots for handling, welding, palletizing and many other applications including robots made in Europe – these will be the key topics at Yaskawa’s Automatica stand (Hall B6, Stand 502).

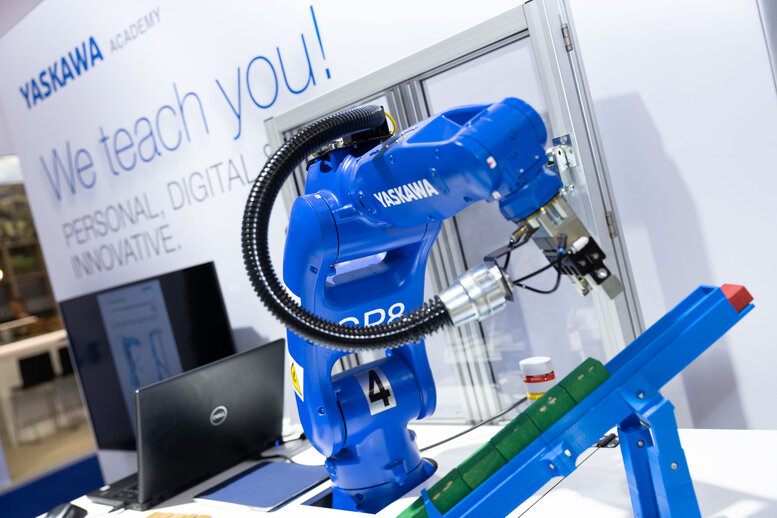

Under the trade fair motto “Robotics Technology for Smart Automation” Yaskawa will be reflecting industry trends. At Automatica, Yaskawa will demonstrate how easy the setup and operation of robots can be today.

The plug&play Cobot Series HC DTP permits fast setup of cobot installations, particularly in the field of palletizing, component handling and welding. With its Ecosystem, Yaskawa offers the appropriate accessories from leading automation partners.

Several cells with the MOTOMAN GP Series (GP stands for general purpose) of 6-axis handling robots will be representative of the extensive MOTOMAN portfolio of classical industrial robots. With different combinations of payload ranges, these robots attend to diverse automated tasks such as handling and manufacturing processes or machine loading.

Many of the displayed robots are made in Europe, being manufactured and in part developed at the Yaskawa plant in Kočevje, Slovenia. With a high level of precision, they not only fulfil the demands of the European market. They ensure short transport routes, a small CO2 footprint and – as of the current date – short delivery times.

With the MOTOMAN PL series Yaskawa presents the current generation of high-performance palletizing robots. These versatile all-rounders are ideal for automatic palletizing and depalletizing. Examples of their fields of application are classical end-of-line packaging and, to an increasingly extent, distribution logistics.

Welding robots of the MOTOMAN AR and MOTOMAN SP series excel in demanding tasks in arc welding and cutting or spot welding.

The ArcWorld family also stands for ready-to-use, compact and low-cost standard welding cells with MOTOMAN robots and safety accessories. Due to its special design, the complete robot cell can be easily shifted if required and immediately put back into operation.

In addition, Yaskawa offers a technical solution for the feedback of robot braking energy to the power circuit – as a standard feature and without additional hardware. All larger MOTOMAN robots of the series, from a payload of approx. 50 kg with the latest YRC1000 robot controller, can convert kinetic energy from downward and lateral movements directly into 400 V alternating current at 50 Hz and feed it back into the grid. Depending on the movement pattern, this significantly reduces the robot’s energy demands.

Last but not least, at Automatica Yaskawa draws attention to its own competence as a leading supplier of drive and servo technology. The current Sigma-7 generation of servo drives used in MOTOMAN robots are among the most compact and at the same time most efficient on the market.

The focus of Yaskawa’s Automatica presentation will be the extensive MOTOMAN portfolio of classical industrial robots in the payload range from 0,5 up to 800 kg.