Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

Yaskawa and Lorch Welding Systems announce Europe-wide cooperation

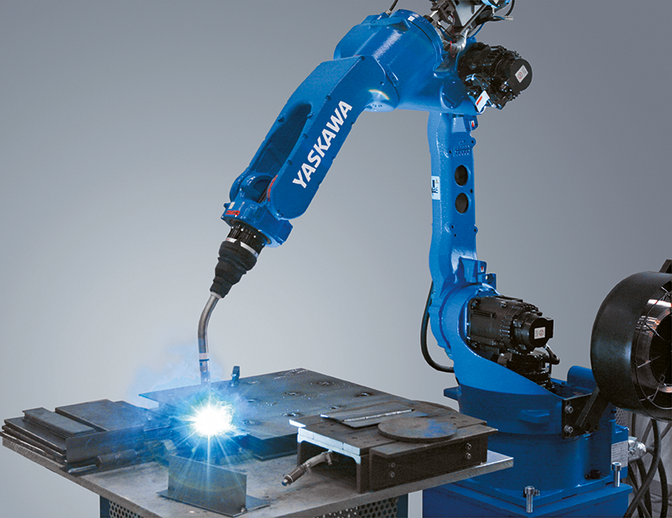

Yaskawa, a global technology supplier in the field of robotics, drive and control technology and Lorch Welding Systems, one of the technology leaders in the field of MIG-MAG welding, announce their future cooperation throughout Europe to provide new innovative solutions to industrial companies in the welding sector. Both partners see an enormous potential especially in medium-sized companies to automate production processes and to adapt existing structures to a digitally modern production in the next years.

"We are the market leader in the welding sector with our broad robot portfolio. In times of collaborative robotics and even closer work cooperation between man and machine, it is obvious that we should cooperate with well-known welding source manufacturers such as Lorch in this field," says Otwin Kleinschmidt, Division Manager Yaskawa Germany.

Wolfgang Grüb, Managing Partner of Lorch Welding Systems: "We are very pleased about the started cooperation with Yaskawa in the field of welding robotics. With this partnership, we will create joint solutions in the future, which will allow customers to further automate their production and to further increase their competitiveness. In the coming years, we see an increasing demand for automated welding solutions, especially in the medium-sized sector but also in large-scale industry. Here we want to jointly increase the efficiency of our customers".

With annual sales of 480 billion yen (around 3.8 billion euros), Yaskawa is a globally active technology supplier in the fields of robotics, drive / control technology and solutions in the energy sector. Founded in Japan in 1915, Yaskawa has been true to its philosophy of supplying products of the highest quality for more than 100 years and has thus achieved a leading position worldwide.

Yaskawa's business activities consist of Drives (GA700 frequency converter), Motion Control (Sigma-7 servo drives and servo motors, machine controllers), Robotics (MOTOMAN industrial robots, robot systems), System Engineering (generators and converters) and Information Technology (software-based products).

MOTOMAN branded industrial robots are used, for example, in robot-based welding, laboratory automation, packaging and handling, and automated painting.

Yaskawa Europe GmbH, headquartered in Eschborn near Frankfurt, is organised in the business units Drives Motion Controls (automation, drive and control technology), Robotics (industrial robots, systems) and Environmental Energy (environmental technology). It serves the markets of Europe, Africa, the Middle East and the former Soviet Union.

The arc welding systems of Lorch Welding Systems for industry, for metal trade and for use in automation have been manufactured for over 60 years in Germany in one of the world's most modern welding system production facilities and exported to more than 60 countries. Due to the direct proximity to the companies and a clear practical orientation, Lorch offers its customers innovative welding applications again and again, which significantly increase the economic efficiency of the companies. The latest innovations are a collaborative welding robot and Lorch Connect, which enables companies to network welding systems without complex IT installations and to have all important welding data always in view.

Contact for readers’ enquiries:

Tel. +49-8166-90-0

Fax +49-8166-90-103