Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

“Ultra” efficient – Ecodesign Directive for variable speed drives

The time has come, July 1, 2021 has passed and the Ecodesign Directive is now also mandatory for variable speed drives. What does that mean exactly, who does it affect, what changes does this entail for Yaskawa’s products? Lots of questions that this article aims to clear up.

What is it all about?

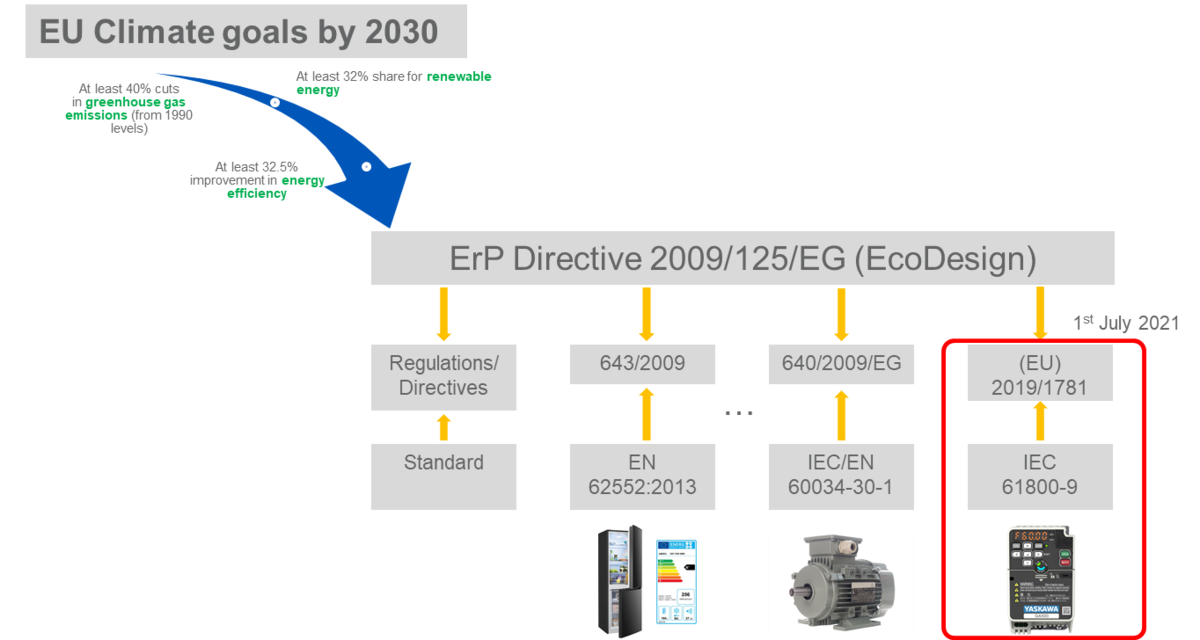

At the heart of the matter are the EU’s climate targets, which were tightened once again in September 2020 under the term “Green Deal” and are to be implemented by 2030 in the first phase. Currently the targets are:

- 55% reduction in greenhouse gases compared to 1990

- A share of at least 32% renewable energies in the energy mix

- At least 32.5% better energy efficiency

The aim is to achieve climate neutrality for the EU by 2050.

To achieve these targets, the ErP (Energy-related Products) Directive was created, which is often referred to as the Ecodesign Directive. It provides a framework but does not contain product-specific requirements, as these are so diverse that they cannot possibly be covered by just one directive. Consequently, implementation regulations have been defined, based on the ErP Directive, which regulate the requirements for the energy efficiency of products.

For example, there are now regulations for all kinds of household appliances, which give us the efficiency class labels we are familiar with on televisions, washing machines, refrigerators, lamps and so on. Similar regulations and labels exist for industrial applications such as compressors, fans, pumps, etc., and electric motors, which are estimated to consume half of the electrical energy produced in the EU, have not been spared. However, it was recognized that much more energy could be saved by controlling the speed of electric motors and so Regulation (EU) 2019/1781 was published, which now regulates the efficiency of the variable speed drive that work alongside the motors.

Which drives are affected?

The scope of the regulation is initially limited to asynchronous machines and variable speed drives suitable for controlling these motors. This means that all other types of motors (e.g. synchronous reluctance, permanent magnet) and frequency inverters intended exclusively for controlling such motors do not fall within the scope.

Furthermore, the scope of the regulation is limited to equipment with a 3-phase input and a power of 0.12 to 1000 kW.

Regenerative or single-phase equipment or equipment with harmonic attenuation and the like are currently explicitly excluded.

In terms of Yaskawa’s product portfolio, this means that servo drives such as the Sigma series and the associated motors, as well as regenerative controllers such as the U1000, D1000 or R1000, need not be considered. It only concerns frequency inverters such as J, V and A1000 and their derivatives or GA500 and GA700. For these, specific efficiency values are now binding and must also be specified.

And how is efficiency determined?

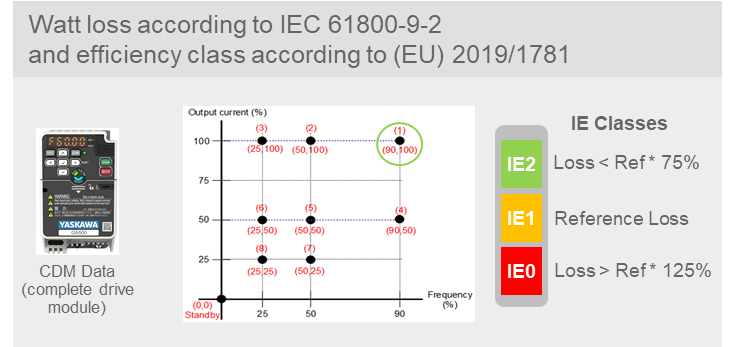

To determine the efficiency of an inverter, the loss values are measured at eight defined load points and in standby according to the IEC 61800-9-2 standard. The loss value at the load point (90, 100) (90% speed, 100% load) is compared with a defined reference value. If it is below 75 % of the reference value, the device corresponds to the highest efficiency class IE2. Frequency inverters that only comply with classes IE0 or IE1 may generally no longer be marketed.

Why use nine points when only one is used?

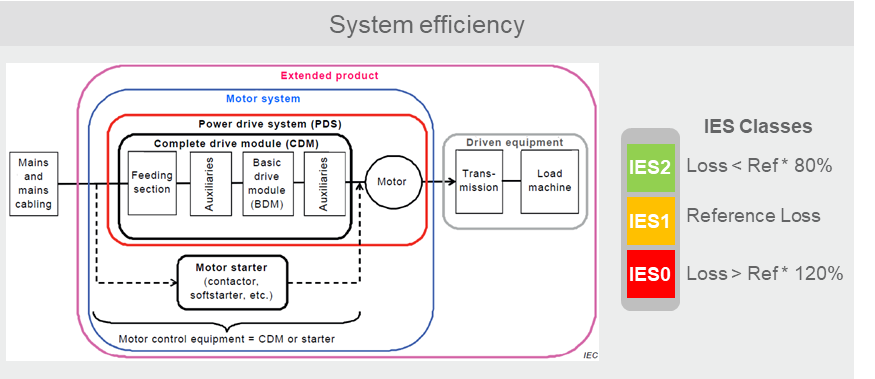

Few machines are actually operated at full load all the time, so efficiency at part load can be much more important in evaluating a system and the (90, 100) point is really secondary. Furthermore, if you want to evaluate and compare the efficiency of machine parts and entire machines, you have to consider all components. The “extended product approach” is aimed specifically at simplifying this.

As a result, the above-mentioned loss values must not only be published for frequency converters, but also for motors at the same operating points. The mechanical engineer can calculate the losses at any operating point using the appropriate formulas from the standard. By adding up the losses of the inverter (CDM) and the motor, you get the losses of the drive system (PDS). If you continue this with the loss values for other electrical and also mechanical components, you end up with the system’s total losses at the various load points and can evaluate its efficiency and also compare it with others.

The system efficiency (motor system or extended product) can be calculated and classified (IES0 to IES2) in the same way as the component using the system’s (90, 100) point.

The EU Commission’s aim is to have an energy classification for all industrial products in addition to consumer products in the future. Economical products should be easily identifiable by the operator, so priority is given to them when investments are being made.

So what does this mean for Yaskawa frequency converters?

From a technical point of view, nothing changes at all. Yaskawa frequency converters have always been efficient and continue to be so to the same extent. They exceed the requirements of efficiency class IE2 without any further action.

Nevertheless, there are some modifications with regard to product labelling and documentation.

First, the efficiency class and at least the relative loss value for the load point (90, 100) must be indicated on the product. In future, both will be included in the information on our inverters’ nameplate. The TÜV logo and RoHS logo are being omitted due to a lack of space. The latter is obsolete anyway, as the RoHS Directive is now a mandatory part of CE conformity and is already covered by the CE logo.

The declarations of conformity (DoC) are also being updated, as compliance with the Ecodesign Directive is now also a prerequisite for being allowed to affix the CE mark. The new DoCs are included with most products, but are of course also available in the download area on www.yaskawa.eu.com.

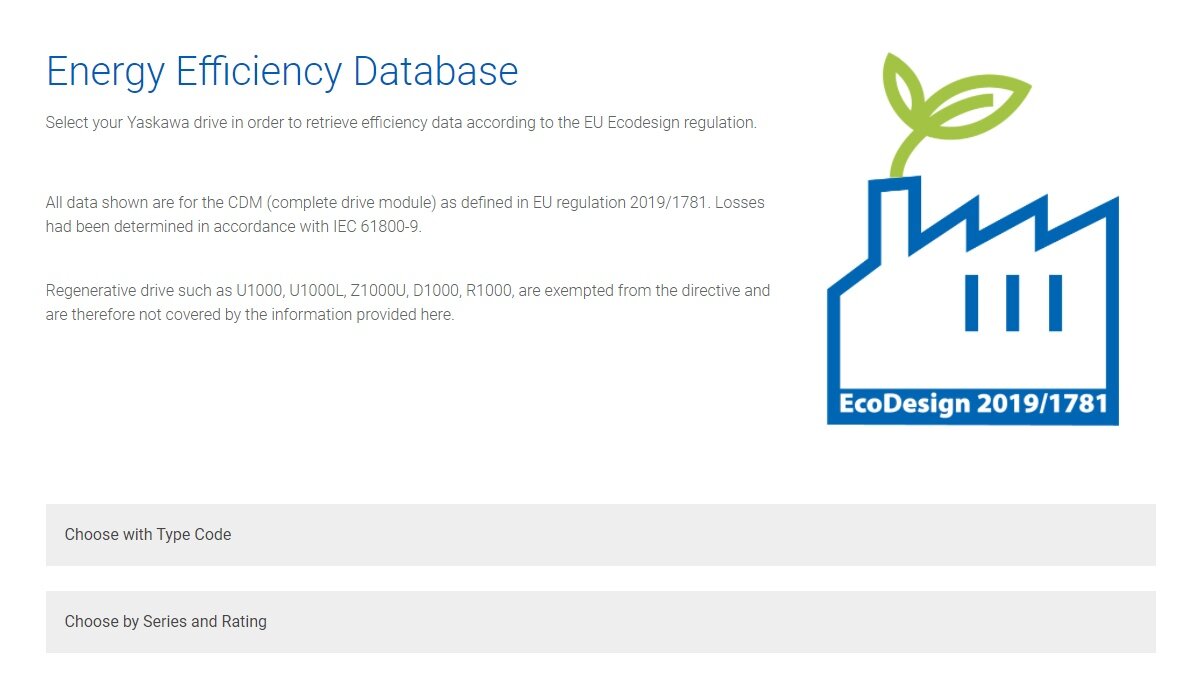

Finally, the loss values at all measuring points must be published together with other specified technical data, although this does not necessarily have to be done in writing. For this reason, there is now a section on our website where the efficiency values for all inverter models can be conveniently accessed (https://www.yaskawa.eu.com/ecodesign). A link to this website is included with each product.

When were the changes implemented?

All inverters placed on the market in the EU after July 1, 2021 must comply with the requirements as above.

At Yaskawa, this applies to all frequency inverters that we manufacture in the EU or import from outside the EU, add to stock and thus place on the market after the deadline. Goods that are in stock are considered to be placed on the market. Therefore, there may be cases where goods that are shipped after July 1 were already in stock before the regulation was implemented. You can continue to use these without hesitation.

The EcoDesign Directive is an important tool for putting a stop to the causes of climate change. Its extension to electric drives is only logical, considering the enormous amounts of energy required by electric drive systems and the potential savings offered.

With the efficient drives from Yaskawa, you can ensure compliance with current and upcoming regulations while also making a strong contribution to energy conservation and climate protection.

Still have questions? Then simply contact our experts.