Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

Autonomous production cell from Yaskawa for bulldozer track roller frames at the Liebherr plant in Telfs (Tyrol)

"A piece of automation history in steel construction"

For decades, the Liebherr company group has been continuously expanding the supposed limits of automation in its production facilities. Now, for the first time, the construction machinery manufacturer is constructing entire complex component groups fully automatically at its plant in Telfs (Tyrol), Austria. The autonomous manufacturing cell developed and built by Yaskawa with three Motoman industrial robots takes over all manipulation and joining processes up to the removal of the finished component.

It all began in 1949 with the invention of the tower crane. Today, the Liebherr Group, headquartered in Switzerland, is one of the largest manufacturers of construction machinery in the world. The brand promise has always remained the same: every machine is a product of the highest engineering skill, incorporating the experience of many decades.

This claim is also continued at Liebherr's production sites: highest quality standards and a very high level of vertical integration are a matter of course there. At the same time, the company has always consistently exploited the possibilities of automation.

Growth through automation

A look at the Austrian Liebherr plant in Telfs shows what this looks like in practice. There, in the Tyrolean Oberland, bulldozers, loaders, telescopic handlers and pipe layers are manufactured. And there are plans to produce significantly more, as Jürgen Vizvary, Project Management Production at Liebherr Werk Telfs GmbH, explains: "We are pursuing a long-term goal at our Telfs plant: to produce over 3,000 units per year. To achieve this, we must consistently focus on automation in factory development. In recent years, we have therefore invested a high three-digit sum in our location, including in a highly automated high-bay warehouse with space for 16,200 euro pallets and 41,180 containers, as well as in the modernization of our assembly lines and steel construction plants. We also want to retain our steel construction expertise in-house in the future despite a shortage of skilled workers.”

As a “lighthouse project for the Liebherr Group's steel construction division,” Jürgen Vizvary and his colleagues have set out to automate the production of three different track roller frames for bulldozers, which were previously manually stapled and welded.

With high expectations, as the project manager explains: "The approach was based on a high-performance concept: fully automated welding that enables high-energy and fully parameterizable welding processes. Another goal was to achieve maximum reproducible quality and at the same time to increase optimization potential in component and welding processes. The focus is on highly integrated, large components in medium quantities, i.e. around 500 units per year."

As a further requirement, not only the stapling and joining processes should be automated, but also the complete handling of all required components. In the words of Jürgen Vizvary, this is “a colorful bouquet of steel construction products - from burned and laser cut parts to castings and raw materials with different manufacturing tolerances - which are combined in the end to form a precise component.”

Picture: The Liebherr plant in Telfs (Tyrol) wants to increase its production to 3,000 devices per year - also by modernizing assembly lines and steel construction plants.

Fully automated welding robot cell as a solution

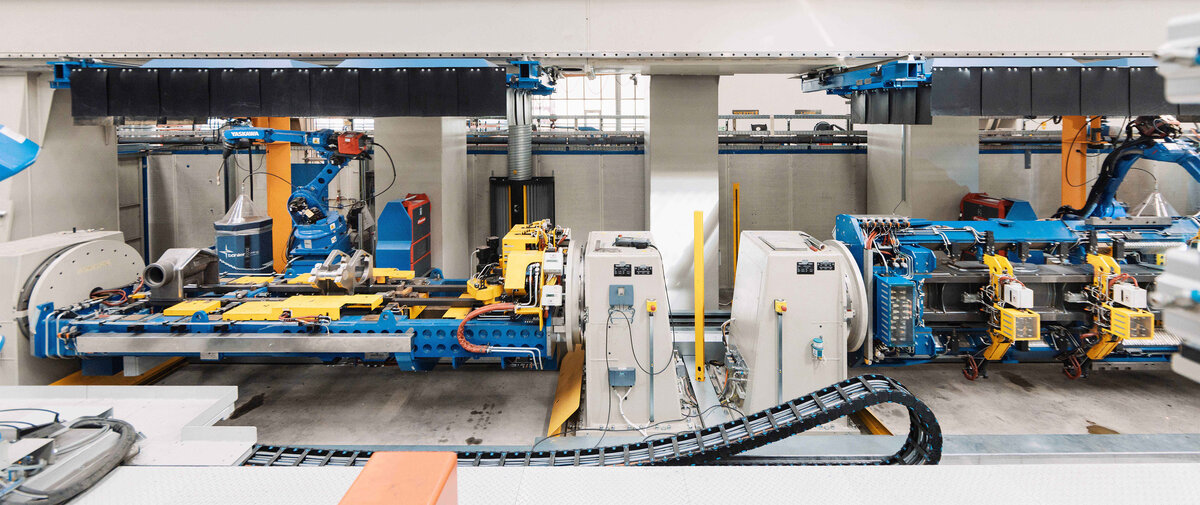

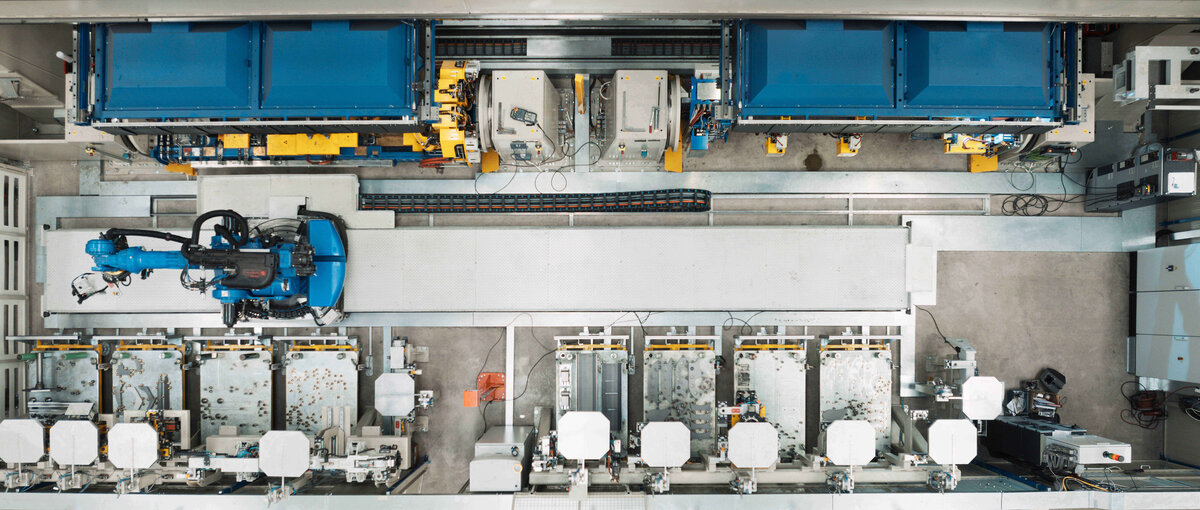

When looking for a suitable solution for this demanding task, a fully automated welding robot cell from Yaskawa was chosen. The plant concept combines a total of four workstations - two welding and two handling areas - on an area of around 22 x 8 m:

In the first station (welding area 1), a welding robot automatically staples and welds the components according to the appropriate welding sequence. A second welding robot then takes over the component for further processing in the second station (welding area 2).

The two welding robots are operated by a handling robot, which takes up the third station (handling zone). This picks up the corresponding individual parts from the various upstream storage positions on the front of the cell. Mounted on a ground track, the handling robot can cover a large working area and easily reach all required positions in the cell. The robot is equipped with different grippers to cleanly grip the various individual components. These can be changed automatically.

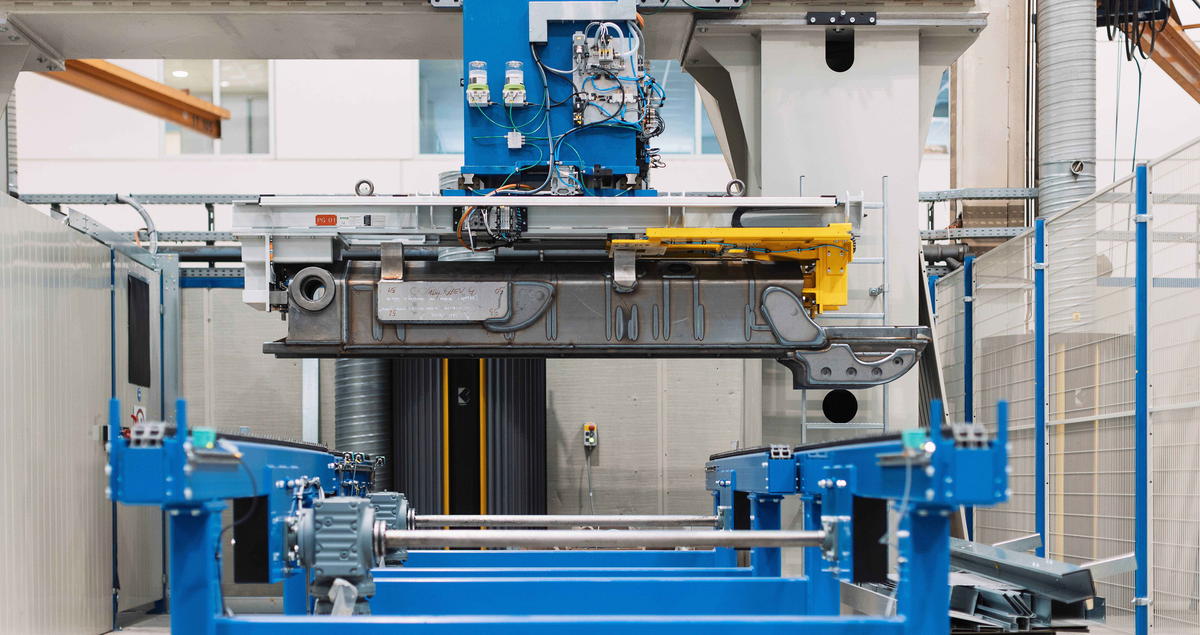

The fourth station of the fully automated cell (finished part handling) finally takes over the removal or conveying of the finished parts via its own handling portal, which is equipped with a special universal gripper.

Thanks to pre-buffering and all the necessary safety precautions, this cell layout allows fully automatic operation, so that the third working shift can even be driven completely unmanned. Overall, the automation measures resulted in an increase in production of over 50 percent.

Picture: The plant concept combines a total of four work stations: two welding stations (pictured above) and two handling areas (center and right outside the image area).

Plant hardware

It is not only the plant concept that comes from Yaskawa. The company, which has its own production sites in Bavaria and Slovenia, also produced the welding and handling robots, including positioners, welding tables and tracks.

The welding robots are two Motoman AR2010 industrial robots. The 6-axis machines are specifically designed for the requirements of arc welding. With a large working area of 2,010 mm and a load capacity of up to 12 kg, they are ideal for welding bulky and large components.

Each robot is equipped with a sidecar to transport the wire drum spool and the power source as well as the burner service station. Both use a common ground track with a travel length of around 12 m, which is fully integrated into the robot control system as an external robot axis. A 6-axle Motoman GP600 with 600 kg payload from the versatile GP series (“GP” stands for “General Purpose”) works in the handling zone.

Picture: The two MOTOMAN AR2010 industrial robots are used for automatic stapling and welding of components.

Two-part, solidly constructed W5000 turner positioning tables are installed in both welding areas, into which the components are clamped using special devices. The maximum load between the tips is 10,000 kg. Each of the four turners has its own drive, i.e. the turners are coupled in pairs as an “electric wave”. The approximately 16 m long XZ portal track was also built by Yaskawa and equipped with in-house drives.

Picture: The welding robots are operated by a MOTOMAN GP600 handling robot, which is mounted on a ground track.

The scope of the implemented system is rounded off by the complete welding torch technology, the complete sensor and control technology, as well as a specially designed extraction and filter system. This is equipped with two movable extraction hoods above the welding stations. This means that the hoods can be swung back so that the component can be removed via the unloading portal. Another special feature is two lifting devices for easy and safe replacement of welding wire drums.

Picture: The extraction and filter system has two movable extraction hoods above the welding stations. This means that the hoods can be swung back to unload (on the right in the picture).

Successfully completed project

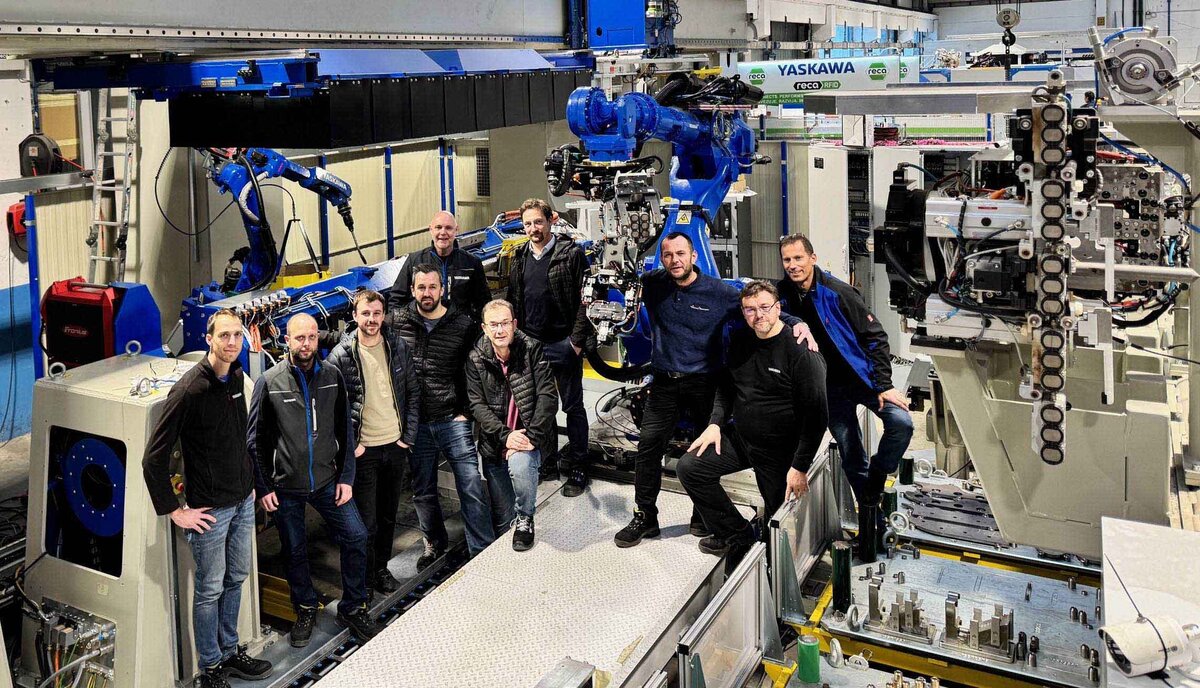

The decision to choose Yaskawa was made as part of an intensive evaluation process in which several providers were given the same task. The contract was awarded in 2022. “From day one, we had a highly professional team from Yaskawa at our side, who supported and accompanied us throughout the project phase,” says Project Manager Jürgen Vizvary from Liebherr.

However, it took some time before the project was successfully completed. In autumn 2025, the fully automated Yaskawa robotic welding system at the Liebherr Telfs plant finally went into operation.

Picture: The finished parts are transported via a separate handling portal, which is equipped with a special universal gripper.

Since then, it has fully met the expectations of Jürgen Vizvary and his colleagues: “The new plant enables the production of complex component groups in steel construction, in which all manipulation and joining processes up to the removal of the finished component are completely automated. We can proudly say that we were part of a development that has rewritten a piece of automation history in steel construction. ”

Author:

Sepp Hautzinger, Sales Manager,

Yaskawa Europe GmbH (Sales Office Austria), Schwechat near Vienna

Contact for readers’ inquiries:

Phone +49-8166-90-0

robotics@yaskawa.eu

Source for all images: © Liebherr

Text: ©Yaskawa Europe GmbH

Video: ©Rossner Dominik (Impressum - Rossner Dominik Fotografie & Film)