More than 100 years committed to technical progress has made us the leading manufacturer in the fields of variable AC drives, servo drives, control technology and robotics.

The Smart Series

Motoman Robots - Plug & Play!

Smart Series Robot Benefits

- Pre-configuration

- User-friendly setup and deployment out of the box

- Perfect for customers that are new to robotics or looking for an easy automation solution.

Simple Robot Programming & Operation

Unlike traditional more complex robot execution, which requires an upfront investment in training, Smart Series technology provides simple, intuitive robot programming and operation methods for your workforce. With a host of grippers and accessories available from our Technology Partners, Smart Series robots can be easily adapted to changing manufacturing requirements and can readily be deployed and redeployed for the next job.

100% Industrial

But with all the simplification, our robots in no way lose their 100% industrial functionality. All our Smart Series robots are controlled by our compact yet powerful YRC1000micro controller. To make the wide range of applications and functions as user-friendly as possible, programming is done via our Smart Pendant with Smart Frame function.

We support you when it comes to implementing your automation solution.

Start your robot journey today!

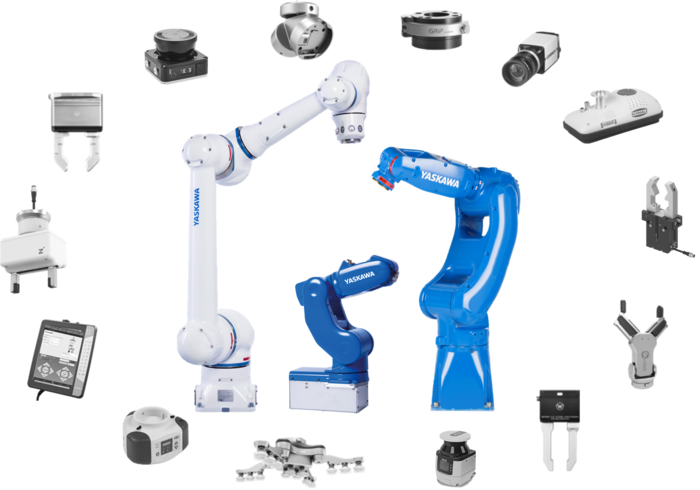

Just choose one of each of the following categories:

- Yaskawa Robots

- Yaskawa Controller + Pendant

- Yaskawa ECOSYSTEM

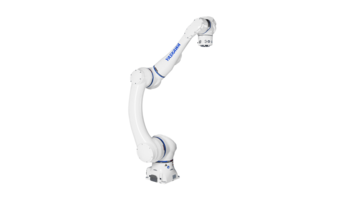

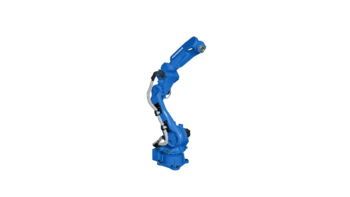

Available are different collaborative robots and small robots up to 12kg payload. These can be used in many different applications; from handling of workpieces, to machine tending, palletizing, assembly or mounting. The smallest of this series is our MotoMINI offering good services wherever precision and highspeed are required within small workspaces.

1. Yaskawa Smart Series Robots

2. Yaskawa Controller & Programming

3. Yaskawa ECOSYSTEM

Yaskawa has partnered with industry leaders to provide interfaces to several robot accessories and total robotic solutions.

By this, Yaskawa helps customers - that are new to robotics - to start their automation story today, as well as robot experts to find new possibilities of intelligent robotic systems.

|

Have a look into more than 90 compatible and plug&play products that help you to quickly meet your application requirements! |

|

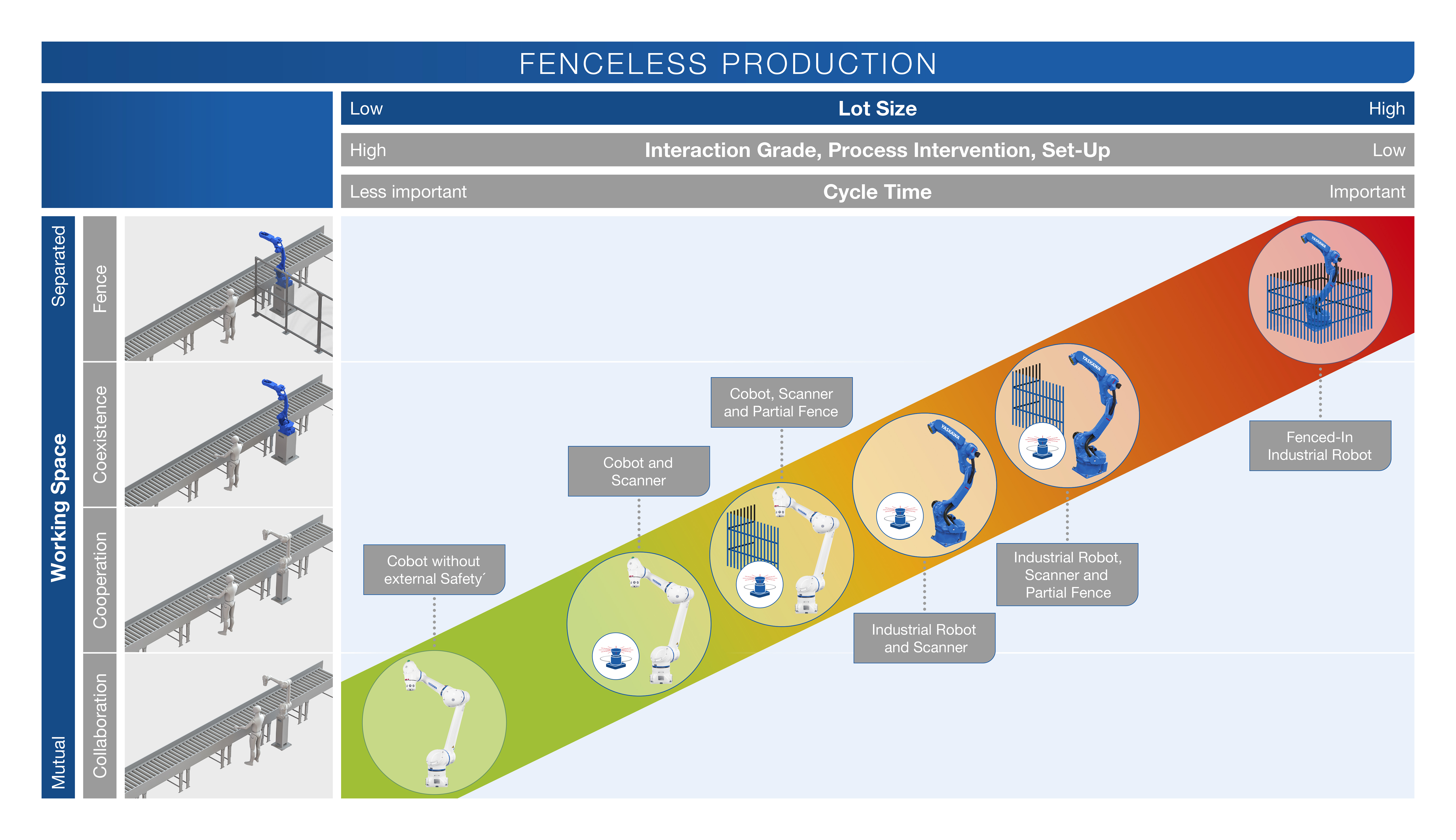

You want to learn more about the Collaborative Modes of our Smart Series robots?

About collaborative robotics

Collaborative robots are being designed as inherently safe to work around people. This involves new ideas for robotic arms including reducing their strength and speed, new types of joints, softer materials, and using advanced sensors to shut down the cobot safely if it accidentally collides with someone.

There are four types of collaborative robot features according to ISO 10218-1 and 10218-2. Each of these features, individually, qualifies a robot as collaborative.

For each mode, Yaskawa offers the best suitable robot to you!

In a collaborative workplace, not only the actual robot interacting with a human worker is considered, but the entire concept of the workstation, equipment and application, as well as the extent and type of human-machine interaction. The result is a complex cell within the production facility that must comply with the standards defined by law. See what services we can offer you to ensure a productive and safe working environment.

Application type:

- Uses laser scanners, light curtains or vision systems to track the worker

Operation procedure:

- Robot works within pre-defined safety zones and acts accordingly when human is detected within the zones (e.g. slows down to 50 % speed, slows down to 20 % speed, stops)

Robot type:

- Standard industrial robot with additional sensing device for safety zone monitoring (e.g. safety scanner or light curtain, etc.)

Example:

- Loading jigs, removing finished products

Application type:

- Used when robot is working mostly alone

- Human interaction with robot is occasional

Operation procedure:

- Human steps into the pre-defined restricted area and the robot stops all movements (servo is on but brakes are applied)

- Robot restarts motion when safety parameters are reset (i.e. human presses the reset button, human leaves red zone of a safety scanner, etc.)

Robot type:

- Standard industrial robot

Example:

- Human performs a secondary operation on a workpiece while robot is holding it

Application type:

- Robot works alongside a human without additional safety devices

Operation procedure:

- Robot monitors external forces applied to its body and performs action (e.g. stop, retreat)

Robot type:

- Not a standard industrial robot, but robot with special force-limited features

- Robot has rounded shapes for dissipation of forces in case of impact

- Depending on the results of a risk assessment, it may not require additional safety devices

Example:

- Machine tending, picking and packing, assembly, etc.

Application type:

- Used for path teaching or hand guiding of the robot

- Pick and place applications

Operation procedure:

- Human switches the robot to TEACH mode

- Robot runs with safety guards in PLAY or REMOTE mode

Robot type:

- Standard industrial robot with additional sensing device (i.e. Kinetiq sensor)

Example:

- Quick and easy path teaching

- Robot guiding during seat assembly in the car body

Successful Smart Series Use Cases

Training and support

Yaskawa supports the entire product life cycle with service products and support to fit any need.

Total Customer Support covers Yaskawa products and systems as well as applications and processes to increase system availability and productivity and to consistently keep everything in top condition.