More than 100 years committed to technical progress has made us the leading manufacturer in the fields of variable AC drives, servo drives, control technology and robotics.

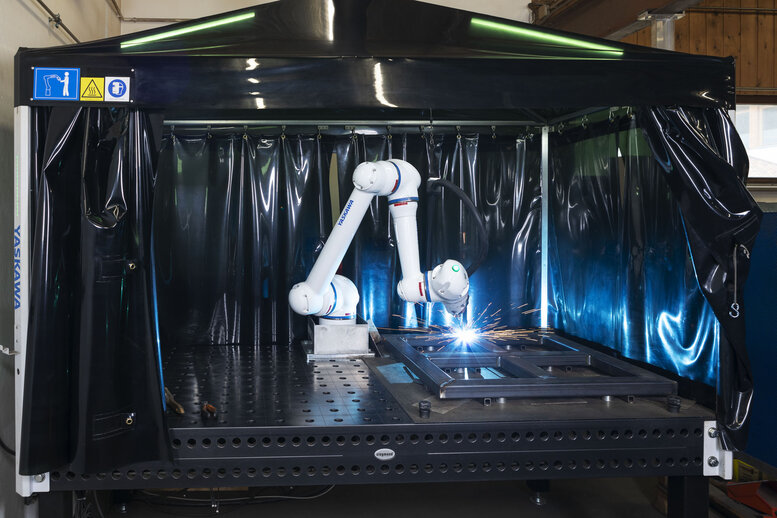

Welding cobot in use at Stöckl Maschinen und Gerätebau

For Stöckl Maschinen und Gerätebau in Schliersee (Germany), the moment finally came when a neighbouring customer placed a large-scale order: this prompted the company to venture into robot-based welding – with a Weld4Me cobot complete cell by Yaskawa.

- Industries

- Metalworking

- Applications

- Human-Robot Collaboration

- Arc Welding

- Client

- Stöckl Maschinen und Gerätebau

Success came literally overnight for Holztec-Leitner based in Schliersee in Upper Bavaria: no sooner had company boss Franz Leitner placed his self-designed, hand-made swing and relaxation loungers made of larch and spruce in an online shop, the first orders started to come in. And numbers have been growing ever since: subject to copyrighted design throughout Europe, the Himmelsliegen (“sky loungers”) are no longer just at home on the banks of Lake Schliersee but on numerous terraces and in gardens and parks as far afield as Mallorca and Italy.

After the initial surprise, Holztec-Leitner quickly realised that a partner was needed to supply the high quantities required on an ongoing basis. The partner was to take over production of the high-quality pivot mounts made of solid metal: the sky loungers are not only attractive and comfortable, they also rotate by 360°.

Successful collaboration

In his search for a suitable specialist, Franz Leitner first tried his luck on his own doorstep in Schliersee – and found just what he was looking for at Stöckl Maschinen und Gerätebau GmbH. “That’s how it all started,” says Kamil Kowalski, one of two Stöckl managing directors, looking back on the beginnings of this successful collaboration.

Established in 1989, the company specialises in the manufacture of welded and assembly components made of steel, stainless steel and aluminium. These are used in traditional machine and device construction, but also in railcars and special vehicles, for example.

Before the enquiry came in from Holztec-Leitner, however, the sophisticated designs were usually only produced in small batches and predominantly by hand. At the end of 2020, Kamil Kowalski and his colleague Christian Strobl took on the challenge of putting together several hundred pivot mounts per year by means of welding – or rather: automated welding. What was needed was a compact robotic welding system that was both quick to commission and easy to operate.

Cobot welding cell as a solution

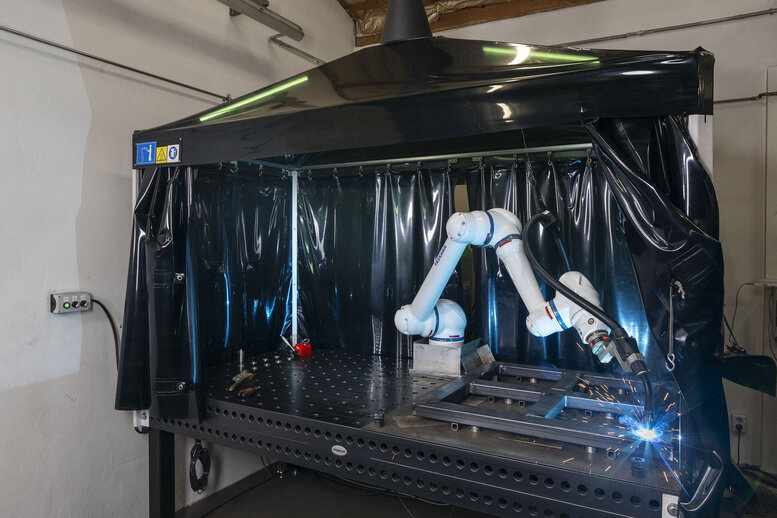

Yaskawa’s Weld4Me cobot welding cell proved to be the ideal solution: it is a compact unit that combines the advantages of a collaborative robot and a simple user interface with professional welding functions. With its decades of experience, the manufacturer is thus able to provide small and medium-sized companies that have previously welded by hand with an optimum way of moving into automated robot welding.

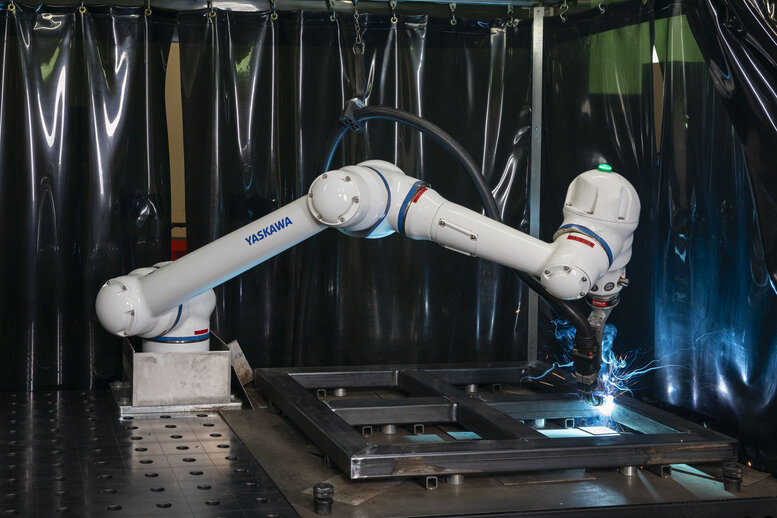

The cell went into operation at Stöckl Maschinen und Gerätebau at the beginning of 2022. As an optional extra, it is equipped with magnetic holders instead of the usual clamping devices. “The cut-to-size profiles are simply inserted and fixed in place magnetically at the touch of a button,” says Kamil Kowalski. “This ensures the components are always in exactly the same place.”

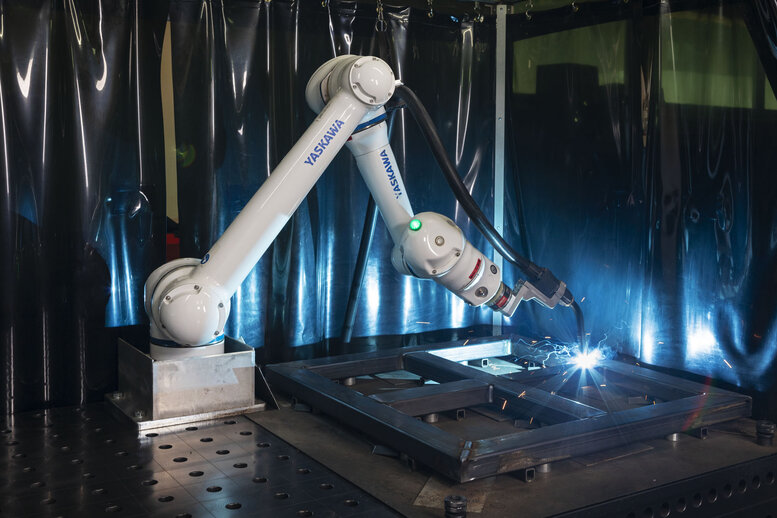

Specifically, the Weld4Me cell consists of a Cobot HC10DT IP67, a YRC1000 controller with functional safety unit (FSU), a welding table, a glare shield and other optional features, as well as extensive functions for MIG/MAG welding. The collaborative robot is designed to meet the requirements of protection class IP67, so it is resilient to welding splashes during the production process. The comprehensive welding package that comes with it consisting of power source, cable package, wire feeder and welding torch is available from numerous well-known manufacturers. Yaskawa now also offers this compact cobot welding solution as a CE-capable Weld4Me CE complete cell.

Programming via Teachbox or manual guidance

The complete cell takes into account the requirements of human-robot collaboration in terms of risk assessment and ensures safe welding operation thanks to the safety set-up. This means that the robot can be set up directly without a fence using integrated torque sensors. As soon as the curtains are closed, it operates in industrial mode.

So even more complex welding tasks can be programmed on the HC10DT IP67 in two alternative ways: in conventional fashion using a programming handset (Teachbox) or by manually guiding the cobot arm (Direct-Teach). Stöckl Maschinen und Gerätebau currently still favours programming via Teachbox, but Managing Director Kamil Kowalski appreciates the Cobot-specific option of hand-guided programming, too. This is because it is easy to move the collaborative robot into new welding positions by manually guiding it, and these positions can be programmed on the simplified “Welding Wizard” user interface. Practical control buttons on the flange also make it easier to programme the welding job. Once the programme has been created, the robot path can be checked again on a dry run before the robot gets to work on the welding. There is no need to learn complex programming environments, so that leaves more time for the actual welding process. This solution is particularly suitable for small batch sizes and a wide variety of products, since it minimises the effort required to change over to a new part.

Practical experience

The new Weld4Me cobot welding cell has been up and running successfully at Stöckl Maschinen und Gerätebau since the beginning of 2022, with a current annual throughput of around 1,000 pivot mounts. “All in all, our entry into robotics has been a success,” says Managing Director Kamil Kowalski, who wouldn’t want to do without the robot: “The Yaskawa welding cobot will remain our only robot for the time being – but it’ll be taking on even more tasks in the future.”

Author and contact for readers’ enquiries:

Jürgen Riedinger, Senior Sales Manager GI Robots & Products

Yaskawa Europe GmbH – Robotics Division, DE-Allershausen

Phone +49-8166-90-0

robotics@yaskawa.eu

www.yaskawa.de

www.mb-stoeckl.de

www.holztec-leitner.de

Contact for the press:

Marion Annutsch

Marketing / PR / Communications

Yaskawa Europe GmbH

P +49-8166-90-0

marion.annutsch@yaskawa.eu